- Packaging

- Flow wrap

Flow wrap

Flow wrap

Details

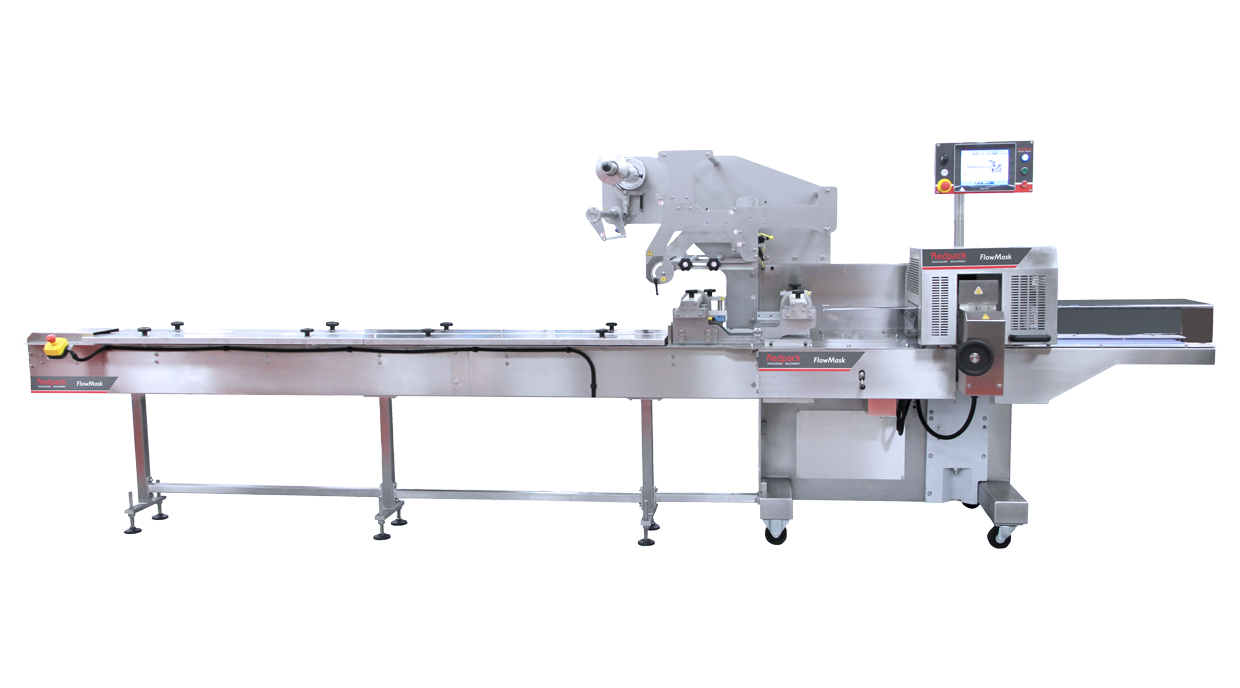

Fox Solutions is proud to partner with Redpack to provide our customers with world class flow wrapping machines for multiple industries and commodities. Redpack’s industry leading flow wrapping machines are designed for versatility, easy configuration, and simplicity of operation. Our team can help you identify the right machine for wrapping:

- with and without tray

- herbs and other delicate items

- difficult-to-handle items

- products requiring a high-integrity seal

Browse more Flexible Packaging Options.

Details

Fox Solutions is proud to partner with Redpack to provide our customers with world class flow wrapping machines for multiple industries and commodities. Redpack’s industry leading flow wrapping machines are designed for versatility, easy configuration, and simplicity of operation. Our team can help you identify the right machine for wrapping:

- with and without tray

- herbs and other delicate items

- difficult-to-handle items

- products requiring a high-integrity seal

Features

Weight Range

8oz – 5lbs.

Printing Process

Surface printing through flexo graphic process produces a high dynamic range of colors

Options

Available perforated and resealable

Downloads

Resources

Display-Ready Packaging Best Practices Checklist

Download this checklist to keep track of all the details involved in launching your next display-ready packaging program.

DownloadDisplay-Ready Packaging

Download to get best practices for putting together a successful display-ready packaging program.

DownloadPackaging Design Creative Brief Template

Download this reusable Microsoft® Word template to ensure your design project is initiated with all the relevant information including project expectations, purpose, audience, brand aesthetics, and competitive landscape.

DownloadFAQ

Flow wrap, also known as horizontal form-fill-seal (HFFS) packaging, is a packaging process used to wrap a product in a flexible packaging material such as a film or foil. The term “flow wrap” is derived from the continuous flow-like motion of the packaging material as it wraps around the product. This packaging method is commonly used for items such as food products, confectionery, bakery goods, and various consumer goods. Here are key features and characteristics of flow wrap packaging:

- Process Overview:

- The flow wrap process involves feeding a continuous roll of flat packaging material (usually a heat-sealable film or foil) through a forming tube or collar.

- The product is placed onto the film, and the film is then folded or wrapped around the product horizontally.

- The edges of the film are sealed longitudinally, creating a sealed tube around the product.

- The product-filled and sealed tube is then cut into individual packages by a cross-sealing mechanism.

- Versatility:

- Flow wrap packaging is versatile and can accommodate a wide range of product shapes and sizes.

- It is suitable for packaging both solid and semi-solid products, making it a popular choice for items like candy bars, cookies, fresh produce, and more.

- Sealing:

- The packaging material is sealed around the product using heat-sealing technology. This ensures a secure and tamper-evident seal.

- Various types of seals can be used, including fin seals and lap seals, depending on the product and packaging requirements.

- High-Speed Production:

- Flow wrap machines are capable of high-speed production, making them efficient for large-scale packaging operations.

- The continuous flow of packaging material allows for rapid wrapping and sealing of individual products.

- Film Options:

- Different types of films can be used in flow wrap packaging, including clear films for product visibility, printed films for branding and marketing, and barrier films for protection against external elements.

- Product Presentation:

- Flow wrap provides a neat and uniform presentation of products, enhancing their visual appeal on store shelves.

- The packaging material conforms closely to the shape of the product, creating a streamlined appearance.

- Tamper-Evident Packaging:

- The heat-sealed closures created during the flow wrap process contribute to tamper-evident packaging. Any tampering with the seal is easily detectable.

- Reduced Material Waste:

- Flow wrap packaging minimizes material waste as the packaging material is used efficiently in a continuous process. This can contribute to cost savings and environmental benefits.

- Ease of Handling:

- Flow wrap packages are easy to handle and open, providing convenience for consumers.

- Tear notches or perforations can be incorporated for easy opening without the need for additional tools.

- Applications:

- Common applications of flow wrap packaging include packaging of candies, chocolates, snack bars, bakery items, fresh produce, frozen goods, and various consumer products.

Flow wrap packaging is a versatile and efficient method for wrapping and sealing products in a continuous process. It is widely used in the food industry and beyond, providing a combination of speed, flexibility, and product presentation.

Flow wrap packaging is versatile and widely used for packaging various types of food products. It is suitable for a range of solid and semi-solid items, providing a secure and visually appealing packaging solution. Here are common types of food that are packaged using flow wrap:

- Candy and Confectionery:

- Flow wrap is commonly used for packaging individual candies, chocolates, and confectionery items. It provides a tamper-evident seal and enhances the presentation of these products.

- Snack Bars:

- Granola bars, energy bars, protein bars, and other types of snack bars are often packaged using flow wrap. The packaging allows for high-speed production and provides a protective seal.

- Bakery Goods:

- Flow wrap is used for packaging a variety of bakery goods, including cookies, brownies, muffins, and individual servings of cakes. The packaging preserves freshness and ensures product integrity.

- Fresh Produce:

- Certain types of fresh produce, such as individual fruits or vegetables, can be packaged using flow wrap. The packaging material may include breathable films to maintain the freshness of the produce.

- Frozen Foods:

- Individual servings of frozen foods, such as ice cream bars, frozen desserts, or single-serve frozen meals, are often packaged with flow wrap. The sealed packaging helps protect against freezer burn.

- Cheese and Dairy Products:

- Flow wrap is used for packaging individual portions of cheese, slices, or wedges. It provides a protective seal and maintains the quality of the dairy product.

- Biscuits and Crackers:

- Individual packs of biscuits, crackers, and other similar snacks are commonly packaged with flow wrap. The packaging helps keep the products fresh and minimizes breakage.

- Fresh and Dried Pasta:

- Individual portions or packs of fresh pasta or dried pasta products can be efficiently packaged using flow wrap. This packaging method ensures product hygiene and presentation.

- Instant Noodles and Soups:

- Single-serve portions of instant noodles, soup packets, and similar products are often packaged with flow wrap. The sealed packaging helps retain flavor and freshness.

- Health and Wellness Products:

- Flow wrap is used for packaging health and wellness products such as nutritional supplements, vitamins, and meal replacement bars. The tamper-evident seal ensures product safety.

- Pet Treats:

- Individual treats for pets, such as dog biscuits or catnip treats, can be packaged using flow wrap. The packaging protects the treats and provides convenience for pet owners.

- Single-Serve Items:

- Various single-serve items, including condiment packets, sugar packets, and coffee sachets, are commonly packaged with flow wrap for easy distribution and use.

- Individual Portions of Cereal:

- Single-serving portions of cereals, muesli, and granola can be efficiently packaged using flow wrap. The packaging protects the contents and allows for convenient consumption.

- Dried Fruits and Nuts:

- Flow wrap is suitable for packaging individual servings or portions of dried fruits, nuts, and trail mix. It helps maintain the freshness and quality of these snacks.

Flow wrap packaging is chosen for its efficiency, versatility, and ability to provide a protective seal for a wide range of food products. The type of packaging material used can be tailored to the specific needs of each food item, ensuring optimal preservation and presentation.

Flow wrap packaging offers several benefits, making it a popular choice for various industries. Here are key reasons why flow wrap packaging is considered beneficial:

- Efficiency and High-Speed Production:

- Flow wrap machines are capable of high-speed production, allowing for efficient and rapid packaging of products. This is particularly advantageous for large-scale manufacturing and packaging operations.

- Versatility in Product Types:

- Flow wrap is versatile and can accommodate a wide range of product shapes, sizes, and types. It is suitable for packaging both solid and semi-solid items, making it applicable to various industries such as food, confectionery, and consumer goods.

- Tamper-Evident Seals:

- The heat-sealed closures created during the flow wrap process contribute to tamper-evident packaging. Any tampering with the seal is easily detectable, ensuring product safety and integrity.

- Product Visibility:

- Flow wrap provides excellent visibility of the packaged product. Consumers can easily see the contents through the transparent packaging, enhancing the overall appeal and marketability of the product.

- Reduced Material Waste:

- Flow wrap minimizes material waste as the packaging material is used efficiently in a continuous process. This can lead to cost savings and aligns with sustainable packaging practices.

- Customization and Branding:

- Products can be customized with printed films, logos, and branding during the flow wrap process. This customization enhances the visual appeal of the packaged items and provides opportunities for branding and marketing.

- Protection and Preservation:

- Flow wrap packaging provides a protective barrier that helps preserve the freshness and quality of the products. The sealed packaging protects against external elements, contaminants, and physical damage during handling and transportation.

- Ease of Handling and Opening:

- Flow wrap packages are easy to handle and open. Tear notches or perforations can be incorporated into the packaging design for easy opening without the need for additional tools.

- Improved Hygiene:

- The sealed nature of flow wrap packaging contributes to improved hygiene by protecting the contents from environmental factors. This is particularly important for food and perishable items.

- Space Efficiency:

- Flow wrap packages are compact and stackable, optimizing space during storage and transportation. This is beneficial for both manufacturers and retailers, especially in environments where space is limited.

- Cost-Effective Transportation:

- The lightweight nature of flow wrap packaging contributes to cost-effective transportation. The reduced weight helps minimize shipping costs for packaged goods.

- Freshness and Shelf Life Extension:

- Flow wrap packaging helps extend the shelf life of products by providing a protective barrier against moisture, air, and light. This is crucial for perishable goods, ensuring that they reach consumers in optimal condition.

- Convenience for Consumers:

- Flow wrap packages are convenient for consumers to handle and open. The packaging is designed for easy access to the product, contributing to a positive user experience.

Flow wrap packaging is beneficial due to its efficiency, versatility, tamper-evident seals, product visibility, reduced material waste, customization options, protection and preservation capabilities, ease of handling, space efficiency, cost-effective transportation, and contribution to improved hygiene. These advantages make flow wrap packaging a preferred choice for various industries seeking efficient and visually appealing packaging solutions.

Yes, flow wrap packaging is also commonly known by another name: horizontal form-fill-seal (HFFS) packaging. Both terms refer to the same packaging process and method. Here’s a brief explanation of the alternative name:

- Horizontal Form-Fill-Seal (HFFS) Packaging:

- “Horizontal Form-Fill-Seal” is a technical term that describes the specific process used in flow wrap packaging.

- “Horizontal” refers to the direction in which the packaging material is fed and formed around the product.

- “Form” indicates the creation of a formed package around the product.

- “Fill” refers to the process of placing the product into the formed packaging.

- “Seal” involves sealing the edges of the packaging material to create individual packages.

These terms—flow wrap and horizontal form-fill-seal—are often used interchangeably, and both describe the continuous packaging process where a product is wrapped in a flexible material that is then sealed horizontally. The choice of terminology may vary depending on industry preferences and specific technical discussions.