- Equipment

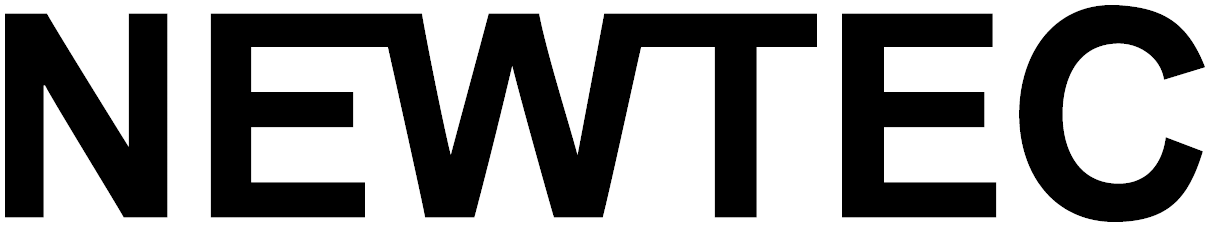

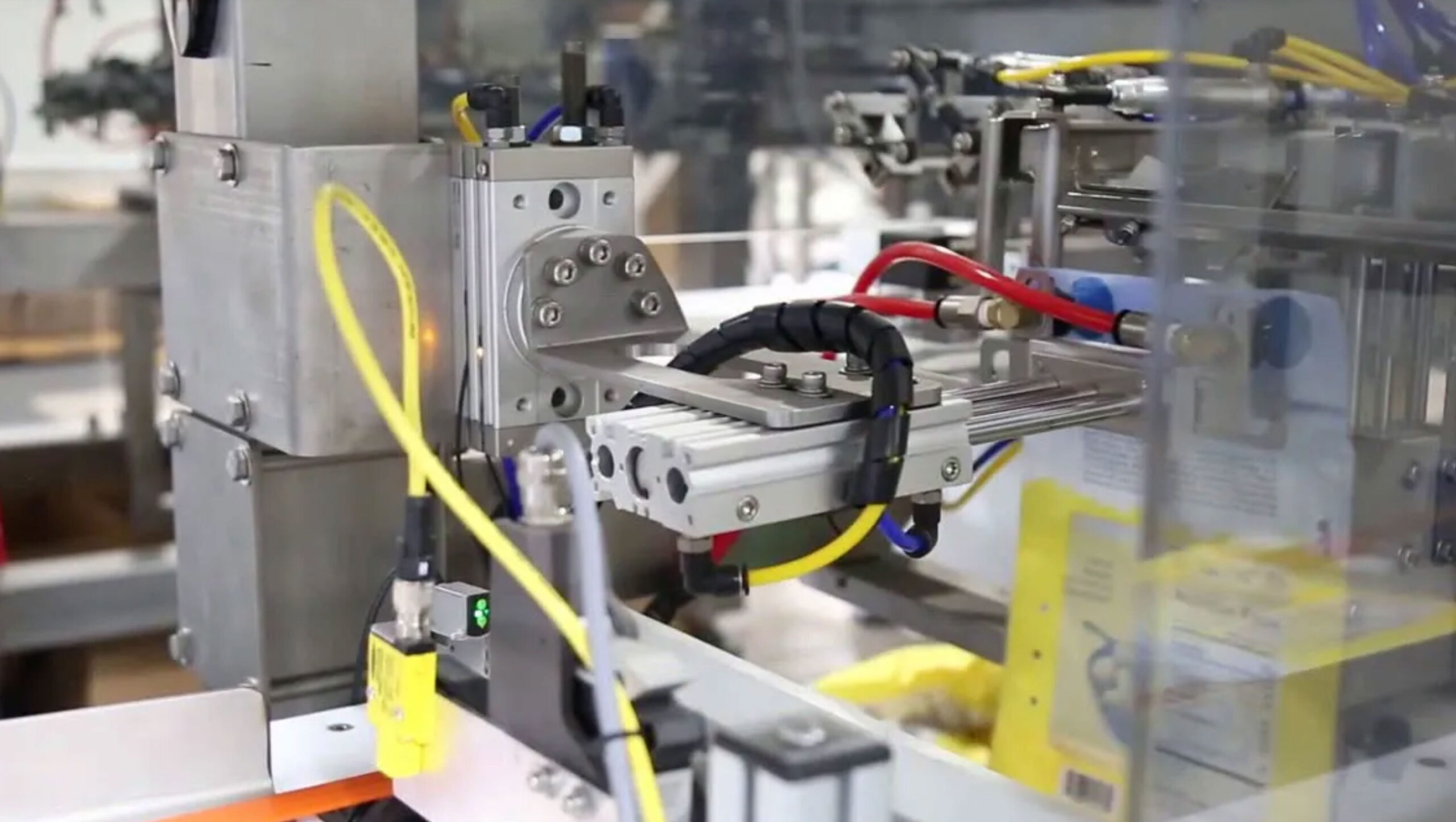

- NEWTEC CheckPoint QC90-2 Weigher

NEWTEC CheckPoint QC90-2 Weigher

NEWTEC CheckPoint QC90-2 Weigher

Works With

Details

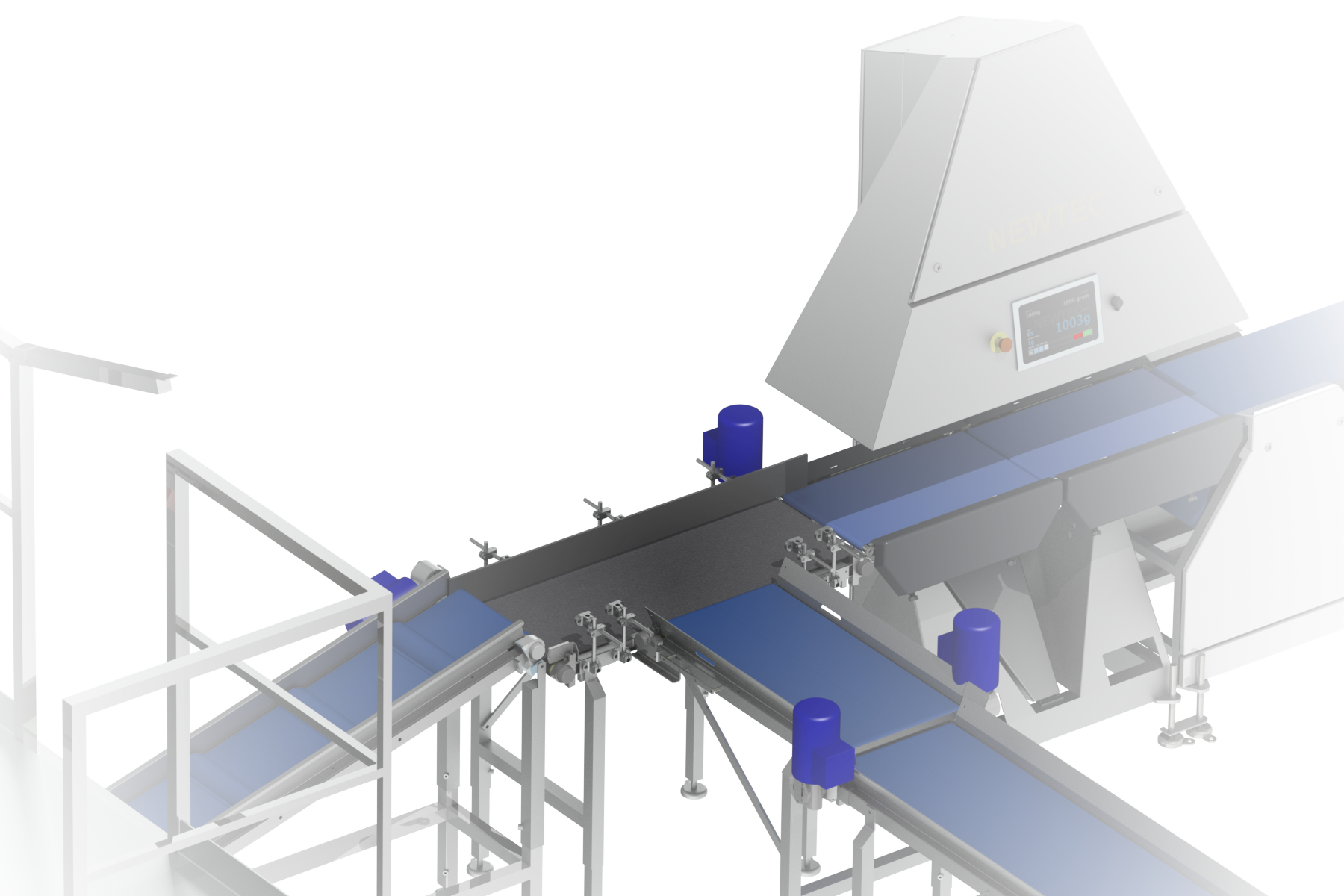

The Newtec CheckPoint QC90-2 Weigher is a high-precision, vision-based end-of-line quality inspection system designed to improve accuracy and reduce packaging errors. Equipped with state-of-the-art vision technology, this advanced system goes beyond weight measurement, ensuring consistent quality control by inspecting packaging material, product placement, and container orientation.

Key Features and Benefits

Highly Accurate Weighing and Vision Control

- In-line weighing with extreme precision, reducing rejected products due to misidentified weight.

- E-weighing technology ensures consistent and reliable measurements.

- Vision control detects loose products, ensuring only properly sealed packaging moves forward.

Intelligent Quality Inspection for Packaging Integrity

- Identifies and rejects packaging errors, such as improperly sealed containers.

- Prevents errors caused by two packages arriving too closely together, avoiding incorrect weight rejection.

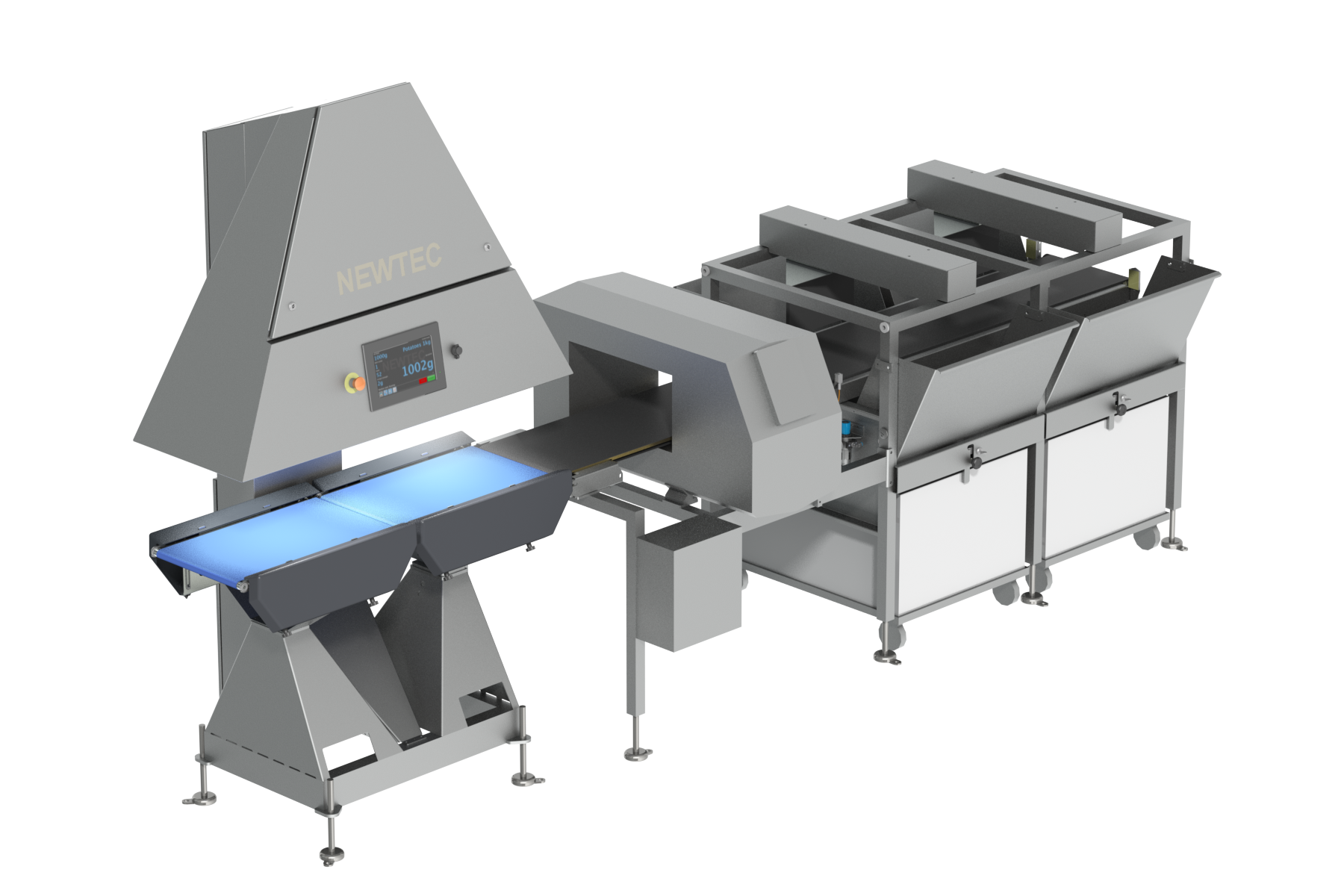

- Adjustable infeed belt speed ensures correct spacing for accurate weight and quality assessment.

Advanced Product Validation and Separation

- Detects form, size, color, orientation, and product angle for container validation.

- Quickly and reliably identifies defects that previously required manual inspection.

- Operator-configurable settings allow customization based on product and packaging requirements.

Seamless Integration and Data Connectivity

- Graphical touchscreen interface simplifies operation and monitoring.

- Newtec WebServices integration enables remote servicing and real-time production data capture.

- MachineLink connectivity allows operators to control both the CheckPoint QC90-2 and connected weighing machines from a single touchscreen.

Optimized for High-Speed Operations

- Processes up to 90 units per minute, ensuring maximum efficiency.

- Extremely robust and accurate load cell guarantees long-term reliability.

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions weighers for advanced weighing and quality control solutions.

Works With

Avocados

Avocados

Pears

Pears

Details

The Newtec CheckPoint QC90-2 Weigher is a high-precision, vision-based end-of-line quality inspection system designed to improve accuracy and reduce packaging errors. Equipped with state-of-the-art vision technology, this advanced system goes beyond weight measurement, ensuring consistent quality control by inspecting packaging material, product placement, and container orientation.

Key Features and Benefits

Highly Accurate Weighing and Vision Control

- In-line weighing with extreme precision, reducing rejected products due to misidentified weight.

- E-weighing technology ensures consistent and reliable measurements.

- Vision control detects loose products, ensuring only properly sealed packaging moves forward.

Intelligent Quality Inspection for Packaging Integrity

- Identifies and rejects packaging errors, such as improperly sealed containers.

- Prevents errors caused by two packages arriving too closely together, avoiding incorrect weight rejection.

- Adjustable infeed belt speed ensures correct spacing for accurate weight and quality assessment.

Advanced Product Validation and Separation

- Detects form, size, color, orientation, and product angle for container validation.

- Quickly and reliably identifies defects that previously required manual inspection.

- Operator-configurable settings allow customization based on product and packaging requirements.

Seamless Integration and Data Connectivity

- Graphical touchscreen interface simplifies operation and monitoring.

- Newtec WebServices integration enables remote servicing and real-time production data capture.

- MachineLink connectivity allows operators to control both the CheckPoint QC90-2 and connected weighing machines from a single touchscreen.

Optimized for High-Speed Operations

- Processes up to 90 units per minute, ensuring maximum efficiency.

- Extremely robust and accurate load cell guarantees long-term reliability.

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions weighers for advanced weighing and quality control solutions.

Downloads

Technical Specs

Maximum Weight

5500 g

Minimum Weight

200 g

Environment

+5 °C to +35 °C, non-condensing, closed location

Accuracy Class

XIII(1)

Maximum Rate of Operation

Target weight < 3000 g: 90 units/min Target weight => 3000 g: 60 units/min

Maximum Product Length

450 mm

Maximum Product Width

350 mm

Ingress Protection

IP 54

Electrical

10A 200-240 VAC

Air Consumption

50 NL, 6 bar

About Company

Newtec is a leading manufacturer of weighing, packing and sorting machinery primarily for the fruit and vegetable industry. With more than 15,000 successful installations over the last 40 years, we have maintained our position as a reputable worldwide company. At Newtec, we pride ourselves on the ability to design solutions that meet your specific needs by combining our machines and the latest technology in new and innovative ways.

We have a reputation for developing, engineering and building high-quality, high-performance machines that our customers rely on.

We focus on building successful long-term relationships with our customers. Understanding your business and the potential challenges it faces is a critical step in order to deliver solutions that make an impactful difference.