- Equipment

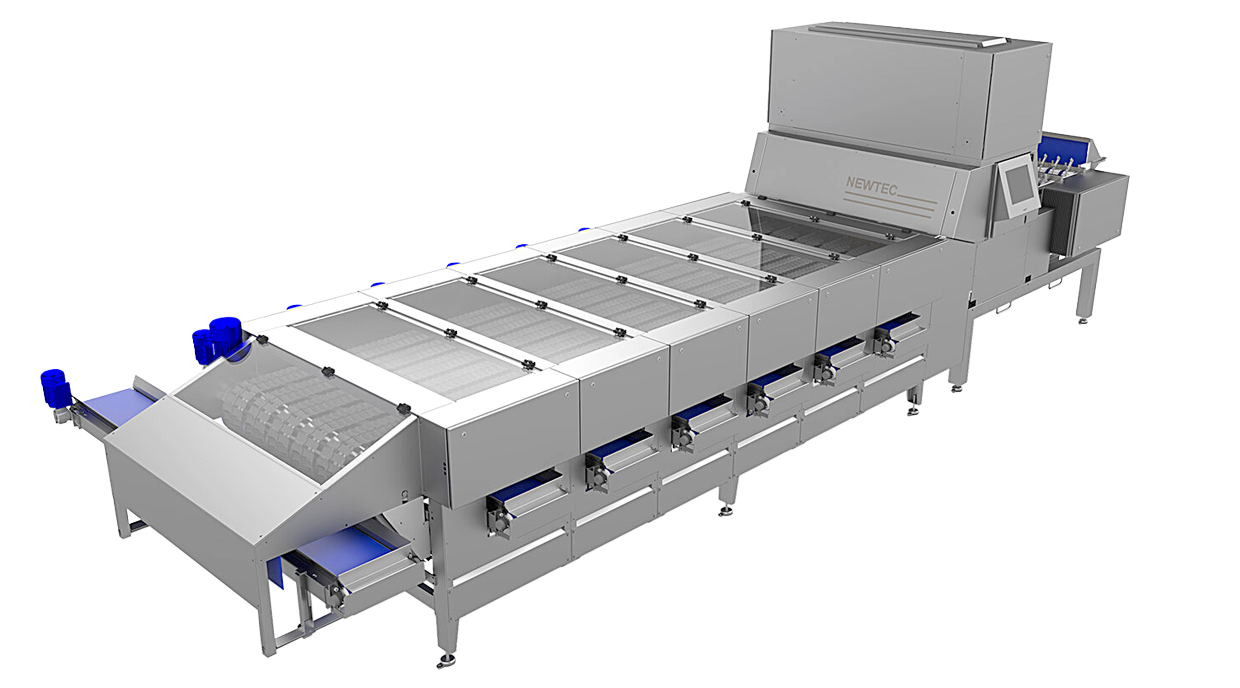

- NEWTEC Celox-P-UHD

NEWTEC Celox-P-UHD

NEWTEC Celox-P-UHD

Details

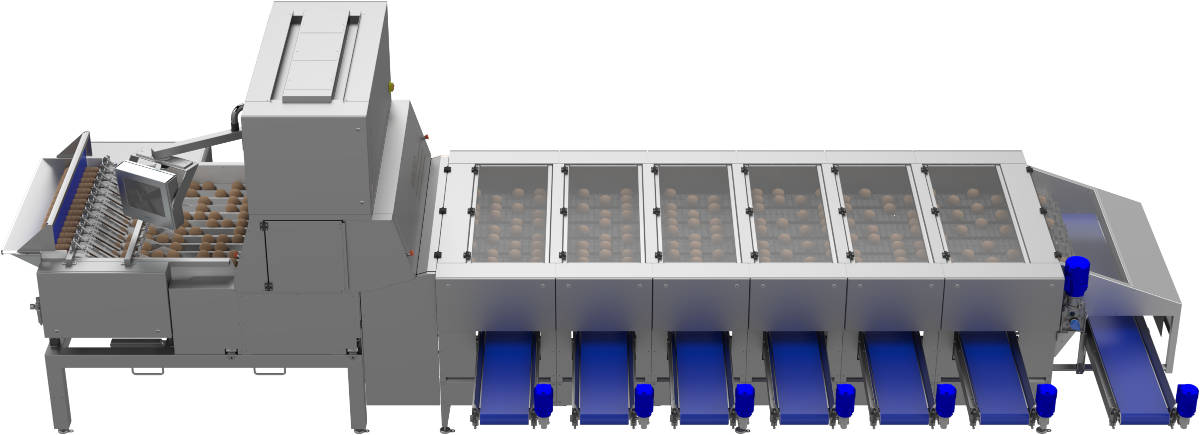

The Newtec Celox-P-UHD is a high-performance optical sorting machine designed to sort washed potatoes by size, shape, and quality in a single-stage process. Available with 2, 4, or 12 lanes, this fully automated system eliminates the need for pre-grading, reduces manual labor, and ensures consistent quality with high throughput.

Key Features and Benefits

High-Speed, Precision Sorting

- Simultaneously sorts up to 13 product categories, optimizing processing efficiency.

- Instantly customizable sorting criteria adapt to changing demands.

- Accurate selection of high-value products, maximizing profitability.

Advanced Technology for Superior Performance

- New generation camera platform ensures high color consistency and precise defect detection.

- Patented technology optimizes sorting accuracy, minimizing waste.

- No need for mechanical pre-grading, reducing processing time and costs.

Optimized Product Handling and Data Integration

- Gentle product handling preserves potato quality and reduces damage.

- Real-time product data collection through Newtec WebServices provides valuable insights.

- Data can be integrated into business IT systems for improved decision-making and production analysis.

Scalable and Cost-Effective Design

- Modular design supports future expansion, allowing sorting of up to 16 categories/outlets.

- Robust stainless steel construction ensures durability in demanding environments.

- Low maintenance costs and labor savings increase operational efficiency.

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions optical sorters and graders for innovative solutions tailored to your processing needs.

Works With

Details

The Newtec Celox-P-UHD is a high-performance optical sorting machine designed to sort washed potatoes by size, shape, and quality in a single-stage process. Available with 2, 4, or 12 lanes, this fully automated system eliminates the need for pre-grading, reduces manual labor, and ensures consistent quality with high throughput.

Key Features and Benefits

High-Speed, Precision Sorting

- Simultaneously sorts up to 13 product categories, optimizing processing efficiency.

- Instantly customizable sorting criteria adapt to changing demands.

- Accurate selection of high-value products, maximizing profitability.

Advanced Technology for Superior Performance

- New generation camera platform ensures high color consistency and precise defect detection.

- Patented technology optimizes sorting accuracy, minimizing waste.

- No need for mechanical pre-grading, reducing processing time and costs.

Optimized Product Handling and Data Integration

- Gentle product handling preserves potato quality and reduces damage.

- Real-time product data collection through Newtec WebServices provides valuable insights.

- Data can be integrated into business IT systems for improved decision-making and production analysis.

Scalable and Cost-Effective Design

- Modular design supports future expansion, allowing sorting of up to 16 categories/outlets.

- Robust stainless steel construction ensures durability in demanding environments.

- Low maintenance costs and labor savings increase operational efficiency.

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions optical sorters and graders for innovative solutions tailored to your processing needs.

Downloads

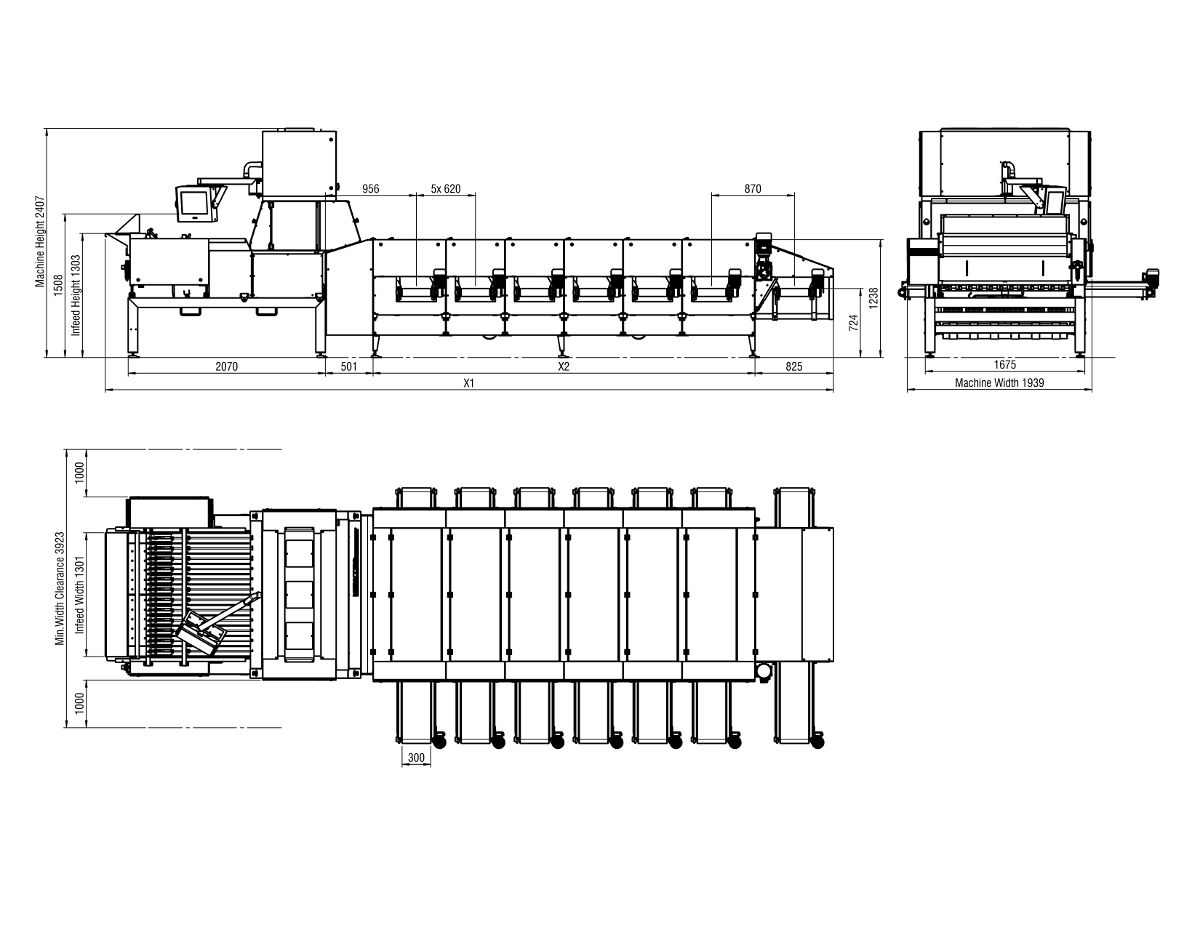

Technical Specs

Capacity (4 lanes)

From 1,5 to approx. 10 tonnes of product/h,

depending on the size of the potatoes.

> Potatoes of 30 g: ~ 1,8 tonnes/hour

> Potatoes of 80 g: ~ 4,2 tonnes/hour

> Potatoes of 300 g: ~ 8,4 tonnes/hour

Capacity (12 lanes)

From 4 to approx. 30 tonnes of product/h,

depending on the size of the potatoes.

> Potatoes of 30 g: ~ 6 tonnes/hour

> Potatoes of 80 g: ~ 14 tonnes/hour

> Potatoes of 300 g: ~ 28 tonnes/hour

Electrical requirement

3x400V+N+PE, 13A

Environment

5°C – 40°C/41°F – 104°F

Weight

From 1200 kg – 3500 kg

Minimum Air Pressure Requirement

6 bar ( 0.6 Mpa)

Consumption

50-100 L/min.

About Company

Newtec is a leading manufacturer of weighing, packing and sorting machinery primarily for the fruit and vegetable industry. With more than 15,000 successful installations over the last 40 years, we have maintained our position as a reputable worldwide company. At Newtec, we pride ourselves on the ability to design solutions that meet your specific needs by combining our machines and the latest technology in new and innovative ways.

We have a reputation for developing, engineering and building high-quality, high-performance machines that our customers rely on.

We focus on building successful long-term relationships with our customers. Understanding your business and the potential challenges it faces is a critical step in order to deliver solutions that make an impactful difference.

FAQ

An optical sorting machine, also known as an optical sorter or vision sorting machine, is a technologically advanced device used in various industries, including food processing, agriculture, recycling, and manufacturing. The primary function of an optical sorting machine is to automatically inspect and sort objects based on their visual characteristics. This is achieved through the use of optical sensors, cameras, and advanced image processing technology. Here are key features and functions of optical sorting machines:

- Detection of Visual Characteristics: Optical sorters use cameras and sensors to capture detailed images of objects as they pass through the machine. These images help the system analyze visual characteristics such as color, size, shape, texture, and defects.

- Automated Sorting Process: The optical sorting machine is equipped with software algorithms that interpret the captured images in real-time. Based on predefined criteria, the system makes rapid decisions to sort objects into different categories.

- High-Speed Operation: Optical sorters are designed for high-speed operation, making them suitable for processing large volumes of materials quickly and efficiently. This is especially valuable in industries with high-throughput requirements.

- Versatility: These machines are versatile and can be used for sorting a wide range of objects, including fruits, vegetables, nuts, grains, seeds, recyclables, minerals, and more. Different models may be optimized for specific applications.

- Removal of Defective or Unwanted Items: One of the main purposes of optical sorting is to remove defective or unwanted items from the production line. This helps improve product quality, reduces waste, and ensures that only high-quality items reach the end of the process.

- Color Sorting: Optical sorters excel at color sorting, making them particularly useful in industries where color is a crucial parameter. For example, in the food industry, they can separate fruits or vegetables based on their color.

- Size Sorting: The machines can also sort objects based on size, ensuring uniformity in the final product. This is beneficial in industries where consistent sizing is important.

- Foreign Material Detection: Optical sorters can detect and remove foreign materials, contaminants, or undesirable items from the product stream, contributing to food safety and quality control.

- Customizable Settings: Operators can often customize sorting parameters, allowing the machine to adapt to different products and sorting requirements. This flexibility is valuable in industries with diverse product lines.

- Integration with Production Lines: Optical sorting machines can be integrated into existing production lines, working seamlessly with other equipment to create a comprehensive and automated sorting process.

Overall, optical sorting machines play a crucial role in enhancing efficiency, improving product quality, and reducing waste in industries that require precise sorting based on visual characteristics.

Optical sorting machines offer various benefits across different industries, contributing to increased efficiency, improved product quality, and reduced waste. Here are key advantages of using optical sorting machines:

- High Precision Sorting: Optical sorting machines provide precise and accurate sorting based on visual characteristics such as color, size, shape, and defects. This ensures that products meet specific quality standards.

- Increased Efficiency: The high-speed operation of optical sorters allows for rapid and continuous sorting, contributing to increased overall production efficiency. This is particularly beneficial in industries with high-volume processing requirements.

- Reduced Labor Costs: Automation provided by optical sorting machines reduces the reliance on manual labor for sorting tasks. This not only lowers labor costs but also minimizes the risk of human error in the sorting process.

- Enhanced Product Quality: By effectively detecting and removing defective or substandard items, optical sorters contribute to improved product quality. This is crucial in industries such as food processing, where quality control is paramount.

- Waste Reduction: Optical sorters help minimize waste by accurately identifying and removing undesirable items or defective products from the production line. This leads to a more efficient use of resources and reduced overall waste generation.

- Color Sorting Capability: In industries where color is a critical parameter, such as agriculture and food processing, optical sorting machines excel at color sorting. This ensures that only products of the desired color or ripeness are included in the final output.

- Foreign Material Detection: Optical sorters can identify and eliminate foreign materials, contaminants, or unwanted items from the product stream. This is particularly important for ensuring food safety and meeting regulatory standards.

- Versatility: Optical sorting machines are versatile and can be adapted to various products and sorting requirements. Different models can be configured to handle different materials and meet specific industry needs.

- Consistent Sizing: Optical sorters can sort objects based on size, ensuring uniformity in the final product. This is valuable in industries where consistent sizing is essential, such as in the sorting of fruits, vegetables, or grains.

- Customizable Settings: Operators can often customize sorting parameters based on the specific characteristics of the products being sorted. This flexibility allows for adaptation to different production lines and product variations.

- Integration with Production Lines: Optical sorting machines can be seamlessly integrated into existing production lines, working in conjunction with other equipment to create a comprehensive and automated sorting process.

- Improved Traceability: Some optical sorting machines offer data collection and reporting capabilities, contributing to improved traceability of products. This can be crucial for quality control, compliance with regulations, and overall process optimization.

The benefits of optical sorting machines include improved efficiency, enhanced product quality, waste reduction, and the ability to meet specific sorting requirements in diverse industries.

An optical sorting machine can be used to sort a wide variety of foods based on visual characteristics. Here are examples of foods that can be effectively sorted by an optical sorting machine:

- Fresh Produce:

- Apples

- Oranges

- Tomatoes

- Grapes

- Berries

- Peaches

- Citrus fruits

- Avocados

- Root Vegetables:

- Potatoes

- Carrots

- Beets

- Onions

- Radishes

- Sweet potatoes

- Leafy Greens:

- Lettuce

- Spinach

- Kale

- Cabbage

- Tree Nuts:

- Almonds

- Walnuts

- Pistachios

- Dried Fruits:

- Raisins

- Dates

- Apricots

- Grains and Pulses:

- Rice

- Lentils

- Beans

- Seeds:

- Sunflower seeds

- Pumpkin seeds

- Sesame seeds

- Processed Foods:

- Frozen vegetables

- French fries

- Breaded products

- Confectionery:

- Chocolates

- Candies

- Gummies

- Meat and Poultry:

- Chicken breasts

- Beef steaks

- Pork chops

- Seafood:

- Fish fillets

- Shrimp

- Dairy Products:

- Cheese blocks

- Butter

- Bakery Products:

- Bread

- Rolls

- Pastries

- Snack Foods:

- Potato chips

- Pretzels

- Popcorn

- Specialty Foods:

- Olives

- Pickles

- Specialty grains

- Processed Fruits and Vegetables:

- Canned fruits and vegetables

- Baby Foods:

- Jars of baby food

- Pouches of baby food

- Pet Food:

- Dry pet food kibble

These examples demonstrate the versatility of optical sorting machines in handling a broad range of food products. The machines use advanced imaging technology to identify and sort items based on parameters such as color, size, shape, and defects. The ability to customize sorting criteria makes optical sorting machines valuable across various stages of food processing and packaging.