- Equipment

- FSDWB4 Bagger

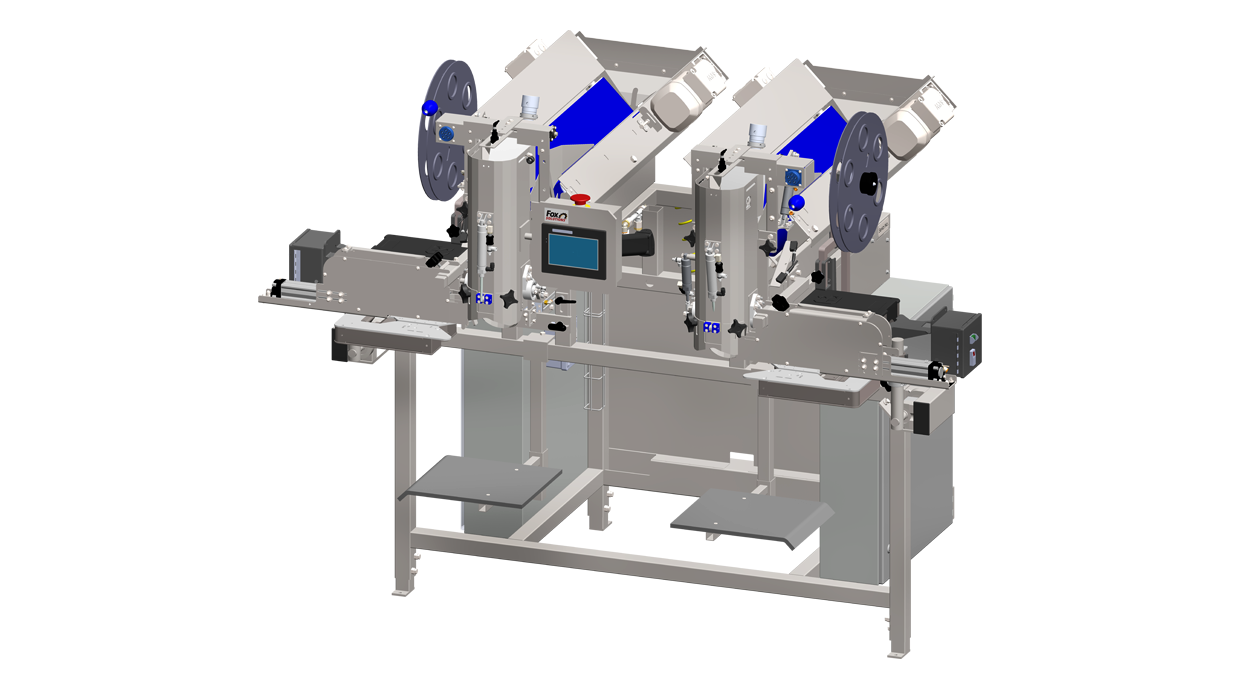

FSDWB4 Bagger

FSDWB4 Bagger

Works With

Details

The Fox Solutions Dual Wicketed Bagger (FSDWB4) is designed for high-volume, automated packing, doubling output while maintaining the same compact footprint as the FSWB3 Single Wicketed Bagger. Built with food safety, efficiency, and ease of maintenance in mind, it features a unique horizontal and vertical feed belt that eliminates jamming before it starts.

Key Features and Benefits

Increased Speed and Productivity

- Packs up to 48 bags per minute, doubling efficiency for high-volume operations.

- Seamlessly integrates with all existing weighers and counters for a fully automated system.

Precision Bag Handling and Filling

- No exposed bag edges prevent bags from being knocked off during filling.

- Single vacuum cup opens bags at the least resistant spot, ensuring smooth and reliable operation.

- Vacuum generator provides controlled suction only when needed, improving efficiency.

Customizable for Different Packaging Needs

- Three toolless quick-change infeed fill chutes accommodate various bag sizes.

- Multiple bag fill conveyor configurations support different produce types.

- Touchscreen controls allow easy program storage and quick adjustments.

- Available in English and Spanish, ensuring user-friendly operation.

Built for Food Safety and Durability

- Constructed from full polished stainless steel, making it easy to clean and maintain.

- Engineered for hygienic operation, meeting strict food safety standards.

- Ideal for lemons, onions, potatoes, oranges, and grapefruit, ensuring gentle yet efficient handling.

Explore compatible bagging solutions, including Poly, Fresh Mesh Combo, and Fresh Mesh Wicketed for a complete packaging system tailored to your needs.

Explore the full range of Fox Solutions Wicketed Baggers to optimize your packing operations.

Works With

Details

The Fox Solutions Dual Wicketed Bagger (FSDWB4) is designed for high-volume, automated packing, doubling output while maintaining the same compact footprint as the FSWB3 Single Wicketed Bagger. Built with food safety, efficiency, and ease of maintenance in mind, it features a unique horizontal and vertical feed belt that eliminates jamming before it starts.

Key Features and Benefits

Increased Speed and Productivity

- Packs up to 48 bags per minute, doubling efficiency for high-volume operations.

- Seamlessly integrates with all existing weighers and counters for a fully automated system.

Precision Bag Handling and Filling

- No exposed bag edges prevent bags from being knocked off during filling.

- Single vacuum cup opens bags at the least resistant spot, ensuring smooth and reliable operation.

- Vacuum generator provides controlled suction only when needed, improving efficiency.

Customizable for Different Packaging Needs

- Three toolless quick-change infeed fill chutes accommodate various bag sizes.

- Multiple bag fill conveyor configurations support different produce types.

- Touchscreen controls allow easy program storage and quick adjustments.

- Available in English and Spanish, ensuring user-friendly operation.

Built for Food Safety and Durability

- Constructed from full polished stainless steel, making it easy to clean and maintain.

- Engineered for hygienic operation, meeting strict food safety standards.

- Ideal for lemons, onions, potatoes, oranges, and grapefruit, ensuring gentle yet efficient handling.

Explore compatible bagging solutions, including Poly, Fresh Mesh Combo, and Fresh Mesh Wicketed for a complete packaging system tailored to your needs.

Explore the full range of Fox Solutions Wicketed Baggers to optimize your packing operations.

About Company

Fox Solutions, LLC sells and supports state-of-the-art, fresh produce equipment solutions. Our team’s vast experience in fresh produce packing gives us unparalleled expertise to help our customers select the best equipment for their commodity and production goals.

Fox Solutions has partnered with a number of best-in-class manufacturers to provide you with optimal food safety construction and performance. We have evaluated a wide variety of custom line configurations and can recommend the right equipment pairings to meet your goals.

Fox Solutions is your single resource for equipment solutions that make the most sense for your business.

Our team is ready to assist with sales, service, parts, repairs, installation, machinery moving, coupling of different machinery makes, and operations consulting.

FAQ

An automated Dual Wicketed Bagger is a packaging machine designed to efficiently and automatically package products using wicketed bags. This type of bagging machine utilizes two wickets, which are metal rods with mounted bags, to streamline the bagging process. The dual wicket system allows for continuous and high-speed packaging of products. Here are key features and components of an automated Dual Wicketed Bagger:

- Wicketed Bags:

- Wicketed bags are bags that are pre-loaded onto metal rods (wickets) in a stacked arrangement. The wickets facilitate easy and quick loading of bags onto the bagging machine.

- Dual Wicket System:

- The “dual” in Dual Wicketed Bagger refers to the use of two wickets in the bagging process. This dual system enhances the efficiency and speed of bag loading, filling, and sealing.

- Automated Operation:

- The machine automates the bagging process, starting from the loading of bags onto the wickets to the final sealing of filled bags.

- Bag Opening Mechanism:

- The machine incorporates a mechanism to efficiently open and present the bags for filling. This can involve separating individual bags from the stack and positioning them for the filling process.

- Product Filling:

- Once the bags are opened, the product filling process begins. This may involve precise dosing or measuring of the product to ensure accurate filling.

- Dual Filling Stations:

- Dual Wicketed Baggers often have two filling stations, allowing for simultaneous filling of two bags. This contributes to increased throughput and efficiency.

- Sealing Mechanism:

- After filling, the bags move to the sealing station. The sealing mechanism securely seals the bags, completing the packaging process.

- Cutting and Separating:

- Once sealed, the bags undergo a cutting process to separate them from the wickets. The individual bags are then ready for further processing or packaging.

- Speed and Efficiency:

- Automated Dual Wicketed Baggers are designed for high-speed operation, making them suitable for industrial-scale packaging with minimal downtime.

- Versatility:

- These bagging machines are often versatile and can be adapted for different bag sizes and types. The dual wicket system enhances flexibility in handling various products.

- Reduced Labor Requirements:

- By automating the bagging process, these machines help reduce the need for manual labor in the packaging line, contributing to operational efficiency.

- Integration with Production Lines:

- Automated Dual Wicketed Baggers are designed to integrate seamlessly with existing production lines. They can be part of a larger automated packaging system in manufacturing facilities.

- User-Friendly Controls:

- These machines typically come with user-friendly controls and interfaces, allowing operators to set parameters, monitor the process, and make adjustments as needed.

- Consistent and Accurate Packaging:

- The automated nature of the dual wicketed bagging process ensures consistent and accurate packaging, reducing errors and improving overall product quality.

An automated Dual Wicketed Bagger is a packaging machine that utilizes two wickets for the efficient and high-speed bagging of products. The dual wicket system enhances productivity and throughput in the packaging process, making it a valuable asset in industries where rapid and consistent packaging is essential.

An automated Dual Wicketed Bagger offers several benefits in the packaging industry, enhancing efficiency, speed, and versatility in the bagging process. Here are key advantages of using an automated Dual Wicketed Bagger:

- High-Speed Operation:

- Dual Wicketed Baggers are designed for high-speed packaging, allowing for rapid and efficient bagging of products. The use of two wickets enables simultaneous filling and sealing, contributing to increased throughput.

- Dual Filling Stations:

- The dual wicket system includes two filling stations, enabling the simultaneous filling of two bags. This dual filling capability enhances the machine’s efficiency and overall productivity.

- Reduced Labor Requirements:

- Automation of the bagging process reduces the dependency on manual labor, leading to labor savings and minimizing the risk of human errors. This is particularly beneficial for large-scale production environments.

- Consistent and Accurate Packaging:

- The automated nature of the Dual Wicketed Bagger ensures consistent and accurate packaging. Each bag is filled and sealed with precision, reducing variability and improving overall product quality.

- Versatility:

- These bagging machines are often versatile and can be adapted for different bag sizes and types. The dual wicket system enhances flexibility, allowing the machine to handle various products and packaging requirements.

- Integration with Production Lines:

- Dual Wicketed Baggers are designed to integrate seamlessly with existing production lines. They can be part of a larger automated packaging system, contributing to a cohesive and efficient manufacturing process.

- Efficient Bag Loading and Opening:

- The automated bag loading and opening mechanism ensures efficient and quick preparation of bags for filling. This contributes to the continuous and uninterrupted operation of the bagging process.

- User-Friendly Controls:

- These machines typically come with user-friendly controls and interfaces, allowing operators to easily set parameters, monitor the process, and make adjustments as needed. This simplifies operation and maintenance.

- Increased Throughput:

- The combination of high-speed operation, dual filling stations, and reduced downtime contributes to increased throughput, making Dual Wicketed Baggers suitable for demanding production requirements.

- Customization for Different Products:

- Manufacturers can customize Dual Wicketed Baggers to meet the specific packaging requirements of different products. This includes adjusting parameters, filling systems, and sealing mechanisms.

- Space Efficiency:

- The compact design of Dual Wicketed Baggers contributes to space efficiency, making them suitable for manufacturing facilities where space is limited.

- Consistent Sealing:

- The sealing mechanism in Dual Wicketed Baggers ensures consistent and secure seals, contributing to the integrity and freshness of the packaged products.

- Reduced Material Waste:

- The efficient use of packaging material in the bagging process helps minimize material waste, leading to cost savings and environmental considerations.

- Hygienic Design:

- Many Dual Wicketed Baggers are designed with hygiene in mind, featuring easy-to-clean surfaces and meeting industry standards for food and pharmaceutical packaging.

- Tamper-Evident Seals:

- The sealing mechanism provides tamper-evident seals, enhancing the security and integrity of packaged products.

The benefits of an automated Dual Wicketed Bagger include high-speed operation, dual filling stations, reduced labor requirements, consistent and accurate packaging, versatility, integration with production lines, efficient bag loading and opening, user-friendly controls, increased throughput, customization options, space efficiency, consistent sealing, reduced material waste, hygienic design, and tamper-evident seals. These advantages make Dual Wicketed Baggers valuable assets in industries where speed, efficiency, and precision in packaging are essential considerations.

An automated Dual Wicketed Bagger is a versatile packaging machine that can be used to package a variety of food products efficiently. Its dual wicket system and high-speed operation make it suitable for different applications. Here are examples of foods that can be packaged with an automated Dual Wicketed Bagger:

- Snack Foods:

- Potato chips

- Pretzels

- Popcorn

- Tortilla chips

- Bakery Products:

- Cookies

- Crackers

- Biscuits

- Croissants

- Candies and Confectionery:

- Chocolates

- Gummies

- Hard candies

- Toffees

- Frozen Foods:

- Frozen vegetables

- Frozen fruits

- Frozen appetizers

- Frozen desserts

- Dried Fruits and Nuts:

- Raisins

- Almonds

- Pistachios

- Trail mix

- Cereal and Granola:

- Breakfast cereals

- Granola

- Muesli

- Fresh Produce:

- Fresh fruits (when packaged with appropriate film)

- Fresh vegetables (when packaged with breathable film)

- Pet Treats:

- Dog biscuits

- Catnip treats

- Small pet treats

- Powdered Foods:

- Coffee

- Tea leaves

- Powdered drink mixes

- Spices

- Dairy Products:

- Cheese cubes or slices

- Yogurt-covered snacks

- Protein Bars:

- Energy bars

- Protein bars

- Grains and Legumes:

- Rice

- Lentils

- Quinoa

- Candy Bars:

- Chocolate bars

- Nut bars

- Fruit and nut bars

- Deli Meats:

- Sliced meats (when vacuum-sealed)

- Herbs and Spices:

- Dried herbs

- Spice blends

- Health and Wellness Products:

- Nutritional supplements

- Vitamin packs

- Specialty Foods:

- Specialty snacks

- Gourmet food products

- Culinary Ingredients:

- Dried mushrooms

- Sun-dried tomatoes

- Specialty flours

- Pasta and Grains:

- Packaged pasta

- Grains (rice, quinoa)

- Instant Noodles and Soups:

- Individual portions of instant noodles

- Soup mixes

The dual wicket system allows for simultaneous filling of two bags, enhancing the efficiency and throughput of the packaging process. It’s important to consider factors such as bag size, packaging material, and product characteristics when configuring the Dual Wicketed Bagger for specific food products. Manufacturers can customize the machine to meet the unique packaging requirements of different foods.

Need a financing quote? No problem!

Contact our finance partner for flexible payment options and tailored financing solutions to support your investment in sustainable packaging and labor-saving equipment.