- Equipment

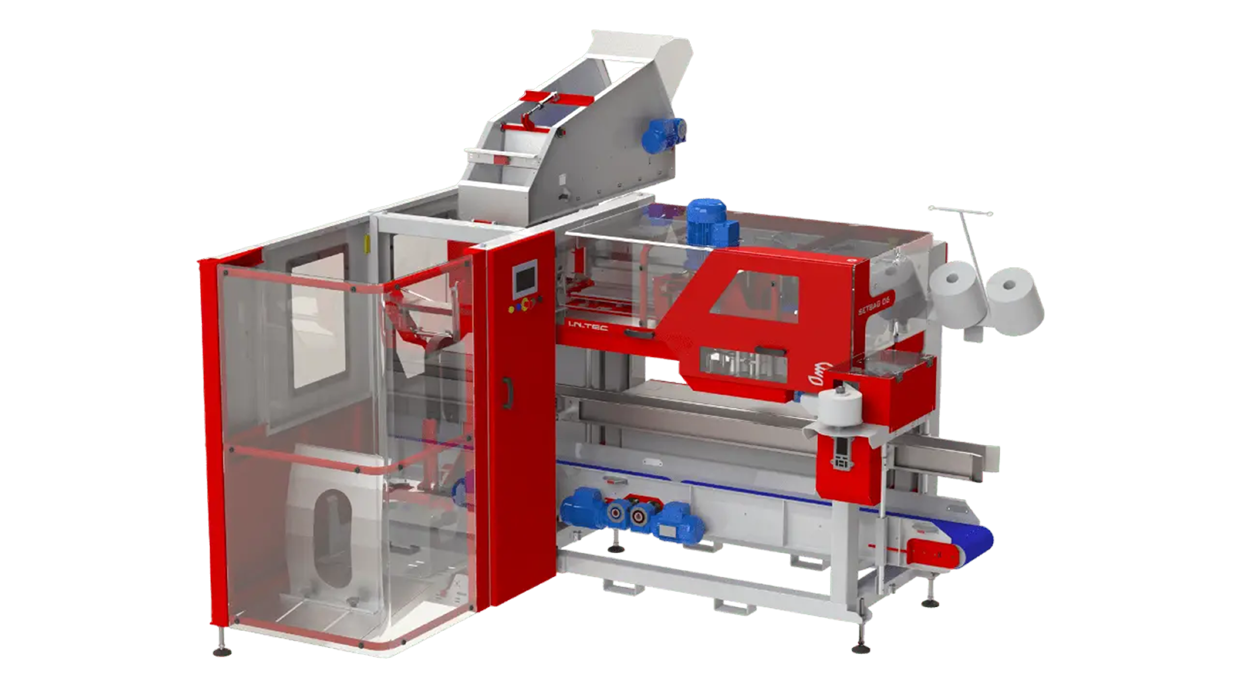

- INTEC BC06 Bagger

INTEC BC06 Bagger

INTEC BC06 Bagger

Details

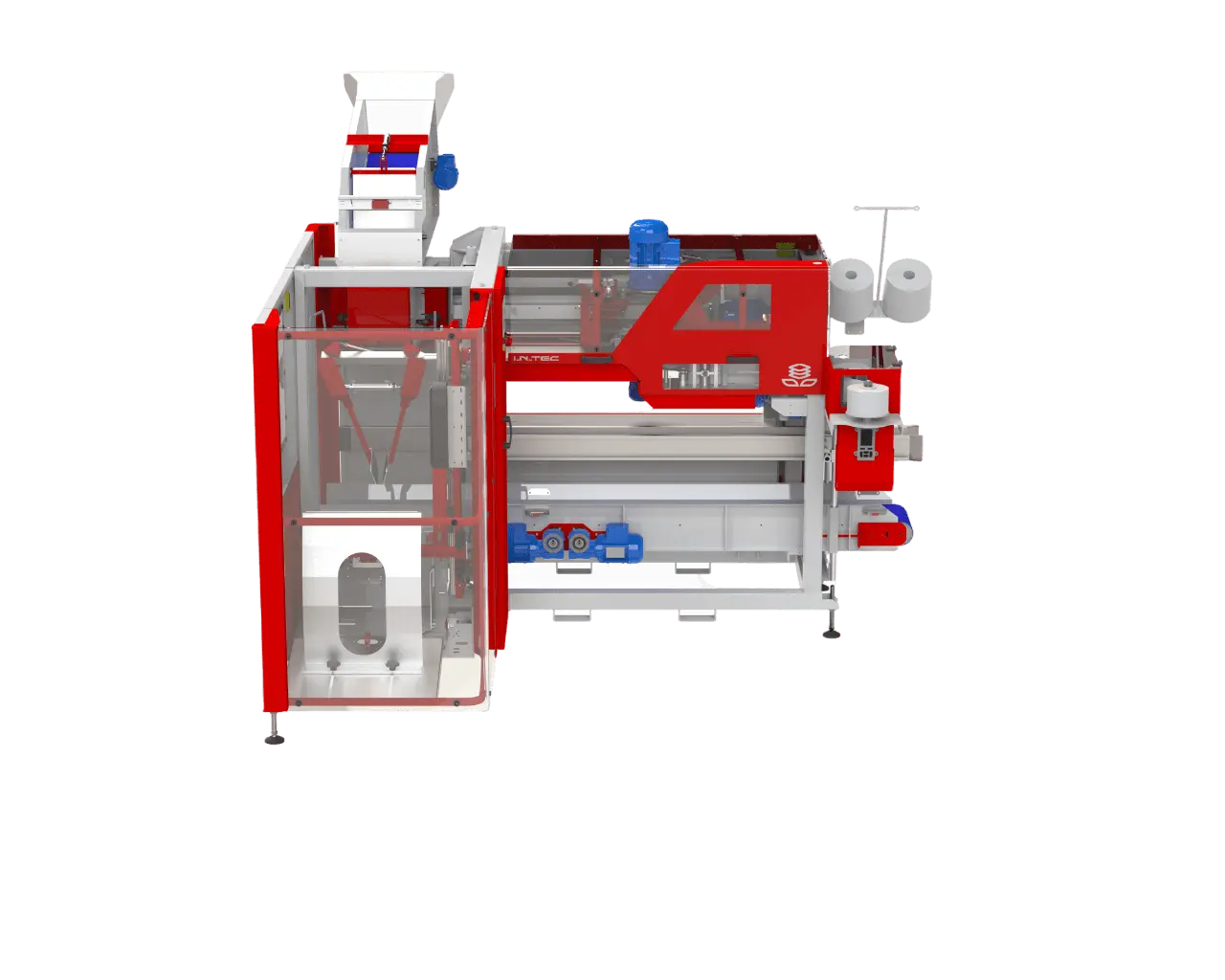

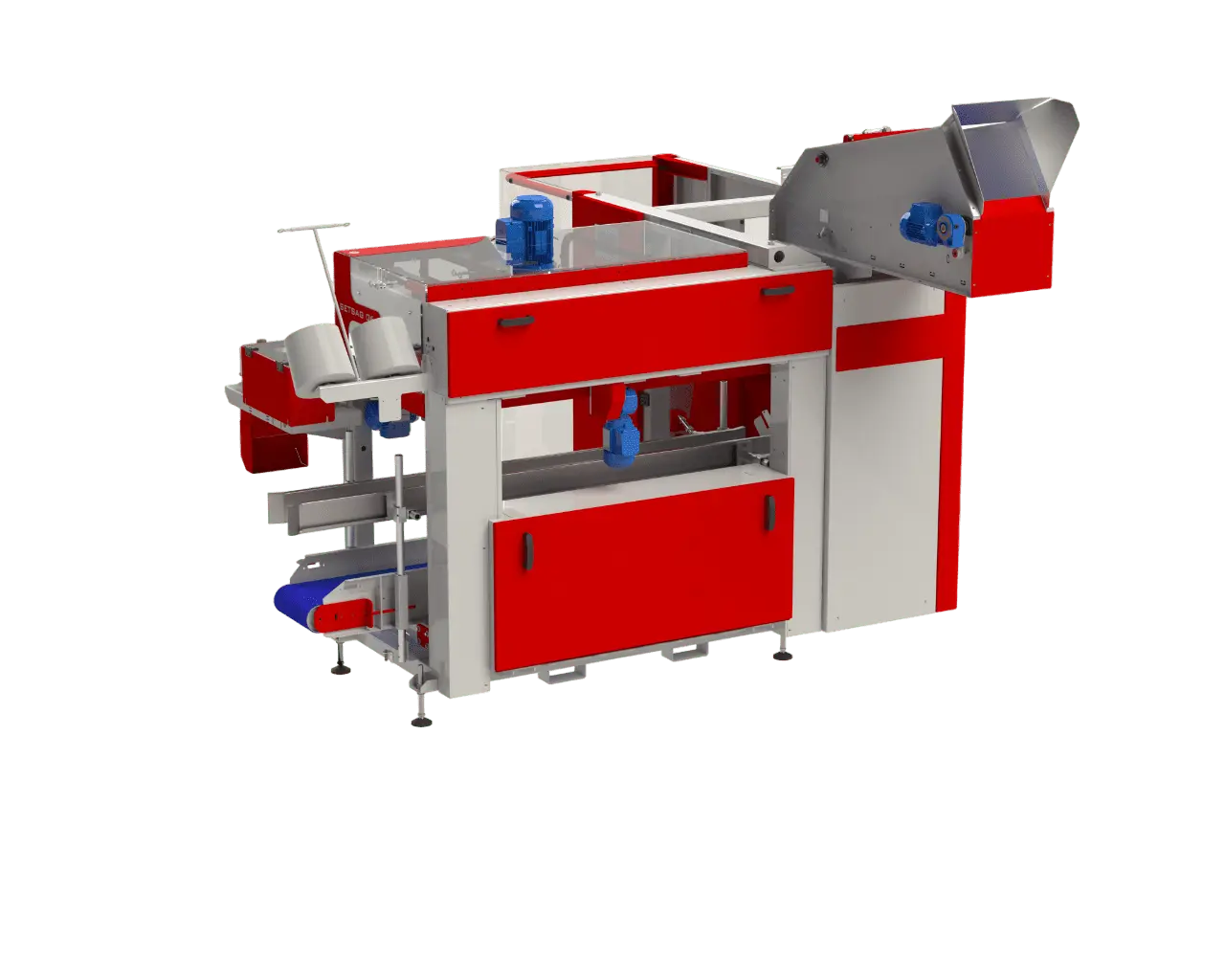

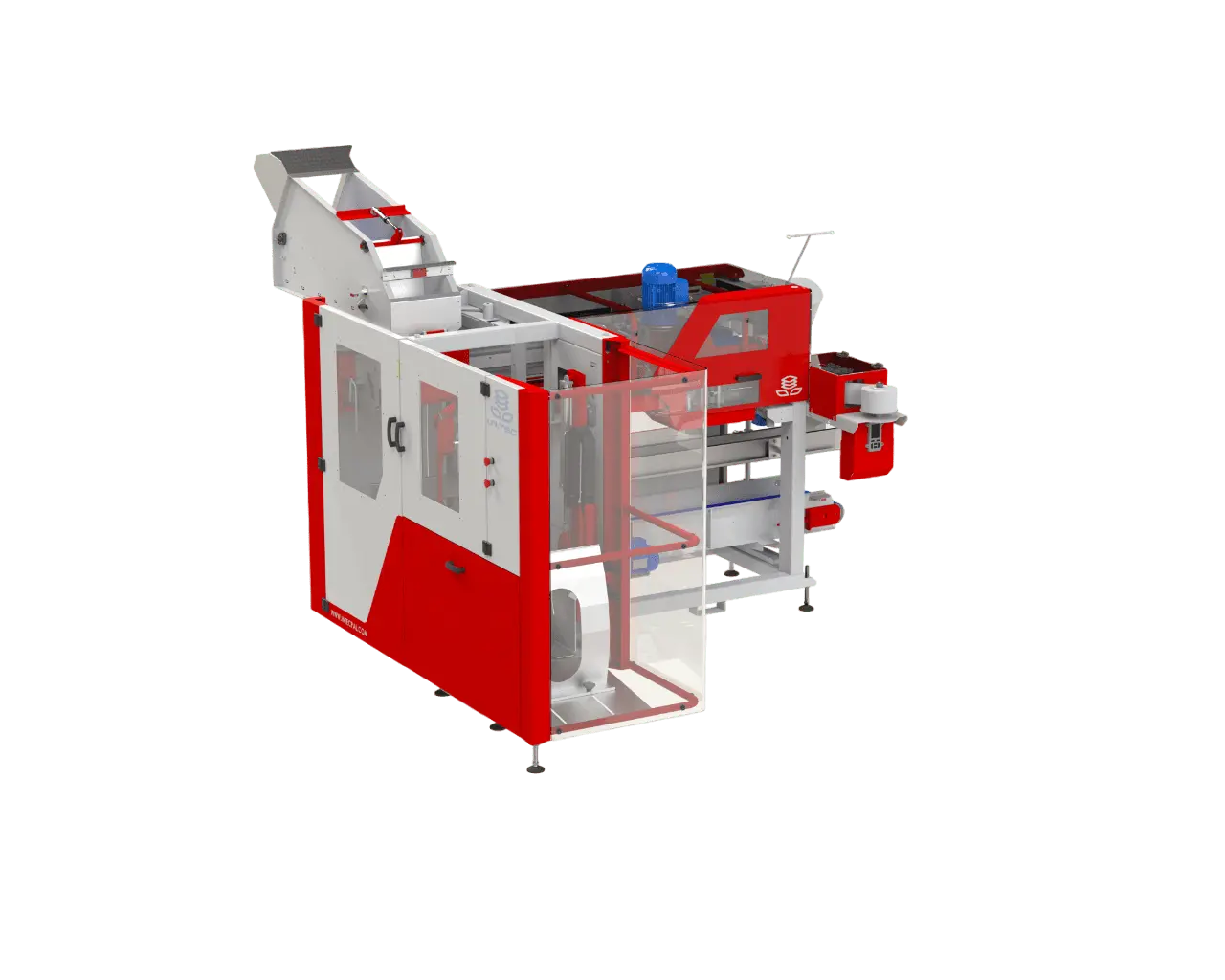

The INTEC BC06 bagger is a large-capacity bag filler designed specifically for fruit and vegetable packaging. This advanced system simplifies the manual placement of bags by extracting them directly from the exit belt after they are packed and stitched. Equipped with an electronic self-adjusting system, the BC06 automatically adapts to different package types and dimensions, ensuring a smooth, efficient operation. Its production speed is fully synchronized with the product dosing machine and bag placement system, allowing it to reach up to 15 bags per minute for high-speed operations.

Key Features and Benefits

High-Speed and Automated Bagging

- Processes up to 15 bags per minute, optimizing productivity.

- Self-adjusting electronic system automatically adapts to bag type and size.

- Fully synchronized with the product dosing machine, ensuring seamless operation.

Advanced Stitching System for Durability

- The INTEC BC06 stitching bench features a sliding stitching head, providing easy access for maintenance and consumable changes.

- Stretching the bag mouth before stitching reduces wear on the stitching machine and improves bag consistency.

Optimized Bag Placement and Handling

- Double traction motor system extracts filled bags at a higher speed than the stitching process, optimizing bag placement time.

- Mouth synchronization ensures precise centering of holders and bags for improved discharge and stitching accuracy.

- Adjustable arm system allows for customized bag width and length for different packaging needs.

Enhanced Accessibility and Visibility

- The BC06 design prioritizes accessibility, ensuring clear visibility throughout the bagging process.

- Fewer optical obstacles reduce errors and improve overall efficiency.

- Transport holder arm synchronization streamlines the placement of recently filled bags onto conveyor belts.

Visit Intecpal at www.intecpal.com/en/ for more information.

See all Fox Solutions equipment for advanced automation in fresh produce packaging

Works With

Details

The INTEC BC06 bagger is a large-capacity bag filler designed specifically for fruit and vegetable packaging. This advanced system simplifies the manual placement of bags by extracting them directly from the exit belt after they are packed and stitched. Equipped with an electronic self-adjusting system, the BC06 automatically adapts to different package types and dimensions, ensuring a smooth, efficient operation. Its production speed is fully synchronized with the product dosing machine and bag placement system, allowing it to reach up to 15 bags per minute for high-speed operations.

Key Features and Benefits

High-Speed and Automated Bagging

- Processes up to 15 bags per minute, optimizing productivity.

- Self-adjusting electronic system automatically adapts to bag type and size.

- Fully synchronized with the product dosing machine, ensuring seamless operation.

Advanced Stitching System for Durability

- The INTEC BC06 stitching bench features a sliding stitching head, providing easy access for maintenance and consumable changes.

- Stretching the bag mouth before stitching reduces wear on the stitching machine and improves bag consistency.

Optimized Bag Placement and Handling

- Double traction motor system extracts filled bags at a higher speed than the stitching process, optimizing bag placement time.

- Mouth synchronization ensures precise centering of holders and bags for improved discharge and stitching accuracy.

- Adjustable arm system allows for customized bag width and length for different packaging needs.

Enhanced Accessibility and Visibility

- The BC06 design prioritizes accessibility, ensuring clear visibility throughout the bagging process.

- Fewer optical obstacles reduce errors and improve overall efficiency.

- Transport holder arm synchronization streamlines the placement of recently filled bags onto conveyor belts.

Visit Intecpal at www.intecpal.com/en/ for more information.

See all Fox Solutions equipment for advanced automation in fresh produce packaging

Downloads

About Company

INTECPAL are specialists in palletizing, bagging and wrapping equipment. Their mission is to design and manufacture the type of machinery that the agro-industrial sector requires, meeting the mechanical, electrical and pneumatic specifications appropriate for each project.

FAQ

A large capacity bagger for fruits and vegetables is a packaging machine designed to handle and efficiently bag a substantial volume of fresh produce. These bagging systems are commonly used in the agricultural and food processing industries to streamline the packaging process for fruits and vegetables, ensuring that products are efficiently packed for distribution and retail.

Key features of a large capacity bagger for fruits and vegetables may include:

- High Throughput:

- These baggers are designed for high-speed operation, allowing them to handle large quantities of fruits and vegetables in a relatively short amount of time.

- Customizable Bag Sizes:

- The machines often offer flexibility in terms of bag size, accommodating various packaging requirements for different types and sizes of fruits and vegetables.

- Versatility:

- Large capacity baggers are versatile and can handle a diverse range of fruits and vegetables, including different shapes and sizes.

- Automatic Weighing and Filling:

- Some baggers are equipped with automatic weighing and filling systems to ensure accurate and consistent packing of produce.

- Adjustable Packaging Configurations:

- The machines may allow for adjustable packaging configurations, enabling operators to customize how fruits and vegetables are arranged and packed in the bags.

- Gentle Product Handling:

- To minimize damage to delicate fruits and vegetables, these baggers are often designed to handle products gently during the packaging process.

- Integration with Sorting and Grading Systems:

- Large capacity baggers may be integrated into larger processing lines, working in conjunction with sorting and grading systems to ensure uniformity in product quality.

- User-Friendly Controls:

- The machines typically feature user-friendly interfaces, making it easy for operators to set parameters, monitor the bagging process, and make adjustments as needed.

- Hygienic Design:

- Considerations for hygiene are crucial in food packaging. Large capacity baggers for fruits and vegetables are often designed with materials and features that facilitate easy cleaning and maintenance.

- Sustainable Packaging Options:

- Some bagging systems may offer options for sustainable packaging materials, aligning with environmental considerations in the industry.

- Sealing Mechanisms:

- These baggers may include sealing mechanisms to securely close and seal the bags, ensuring the freshness and integrity of the packaged fruits and vegetables.

- Packaging Line Integration:

- Integration with other packaging line components, such as labeling machines, date coders, and palletizing systems, for a seamless end-to-end packaging process.

- Durability and Reliability:

- Large capacity baggers are built to withstand continuous operation in industrial settings, with durable construction and reliable components.

These bagging machines are essential for efficiently packaging bulk quantities of fruits and vegetables, helping producers and processors meet market demands while maintaining product quality and freshness. The specific features and capabilities may vary among different models and manufacturers.

A large capacity bagger for fruits and vegetables offers several benefits to producers, processors, and distributors in the agricultural and food industries. These benefits contribute to increased efficiency, improved product presentation, and enhanced market readiness. Here are key advantages of using a large capacity bagger for fruits and vegetables:

- High Throughput:

- Large capacity baggers are designed for high-speed operation, allowing for the efficient processing and packaging of large volumes of fruits and vegetables in a relatively short time.

- Cost Efficiency:

- By automating the bagging process, these machines reduce the reliance on manual labor, leading to cost savings in terms of labor expenses. The increased throughput also contributes to overall cost efficiency.

- Consistent and Uniform Packaging:

- The bagger ensures consistent and uniform packaging, helping maintain a standardized appearance for the packaged fruits and vegetables. This consistency enhances the product’s market appeal and branding.

- Versatility:

- Large capacity baggers are versatile and can handle a wide variety of fruits and vegetables, accommodating different shapes, sizes, and types of produce.

- Reduced Product Handling:

- Automation minimizes the need for excessive product handling, reducing the risk of damage to delicate fruits and vegetables. Gentle handling mechanisms contribute to maintaining product quality.

- Customizable Bag Sizes:

- The ability to customize bag sizes according to product specifications and market requirements provides flexibility in packaging. This adaptability is crucial for meeting diverse customer demands.

- Efficient Weighing and Filling:

- Automatic weighing and filling features ensure accurate and consistent packing of produce, reducing the likelihood of underfilling or overfilling bags.

- Improved Hygiene and Sanitation:

- Large capacity baggers are designed with hygiene in mind, featuring materials and designs that facilitate easy cleaning and maintenance. This is essential for meeting food safety standards.

- Integration with Sorting Systems:

- Integration with sorting and grading systems ensures that only high-quality fruits and vegetables are selected and packaged. This contributes to uniformity in product quality.

- User-Friendly Controls:

- The machines typically feature user-friendly interfaces, making it easy for operators to set parameters, monitor the bagging process, and make adjustments as needed.

- Enhanced Shelf Presentation:

- Consistent and well-packaged fruits and vegetables contribute to an appealing shelf presentation, attracting consumers and influencing purchasing decisions.

- Optimized Space Utilization:

- Efficient packaging configurations and stacking facilitated by the bagger contribute to optimized space utilization during storage and transportation.

- Sealing Mechanisms for Freshness:

- Baggers often include sealing mechanisms that securely close and seal the bags, preserving the freshness and extending the shelf life of the packaged fruits and vegetables.

- Compliance with Sustainable Packaging Trends:

- Some baggers offer options for sustainable packaging materials, aligning with industry trends and consumer preferences for environmentally friendly packaging.

- Integration into Packaging Lines:

- Large capacity baggers can be seamlessly integrated into broader packaging lines, facilitating a streamlined end-to-end packaging process with other components like labeling and palletizing systems.

A large capacity bagger for fruits and vegetables provides numerous benefits, including increased efficiency, cost savings, consistent packaging, versatility, improved hygiene, and enhanced product presentation. These advantages contribute to the overall competitiveness and market readiness of packaged fruits and vegetables in the food industry.

A large capacity bagger for fruits and vegetables is versatile and can handle a wide variety of produce, accommodating different shapes, sizes, and types of fruits and vegetables. The specific capabilities may vary based on the design and features of the bagging machine, but in general, a large capacity bagger can be used to bag the following fruits and vegetables:

- Apples

- Oranges

- Bananas

- Grapes

- Berries (strawberries, blueberries, raspberries)

- Citrus fruits (lemons, limes, grapefruits)

- Peaches

- Nectarines

- Plums

- Avocados

- Kiwi

- Pears

- Cherries

- Mangoes

- Pineapples

- Melons (watermelons, cantaloupes, honeydews)

- Pomegranates

- Tomatoes

- Cucumbers

- Bell peppers

- Zucchini

- Carrots

- Celery

- Broccoli

- Cauliflower

- Lettuce and salad greens

- Spinach

- Kale

- Brussels sprouts

- Asparagus

These examples represent a range of fruits and vegetables commonly found in supermarkets and grocery stores. Large capacity baggers are designed to handle products with different weights, shapes, and packaging requirements. The versatility of these machines makes them suitable for use in various sectors of the agriculture and food processing industries. The bagging process helps maintain the freshness and quality of the produce, ensuring it reaches consumers in an organized and appealing manner.