- Equipment

- NTS Top Seal

NTS Top Seal

NTS Top Seal

Details

Key Features and Benefits

- Precision engineered components housed in a stainless steel fabrication

- Cantilever design to enhance hygienic cleaning and improve maintenance access

- 24/7 production capability

- Multi-axis electronic drive system with touch screen

- 50 product settings that automatically change the bag length, print registration, end crimp slow down, in feed position, machine

- 20 – 250 packs per min.

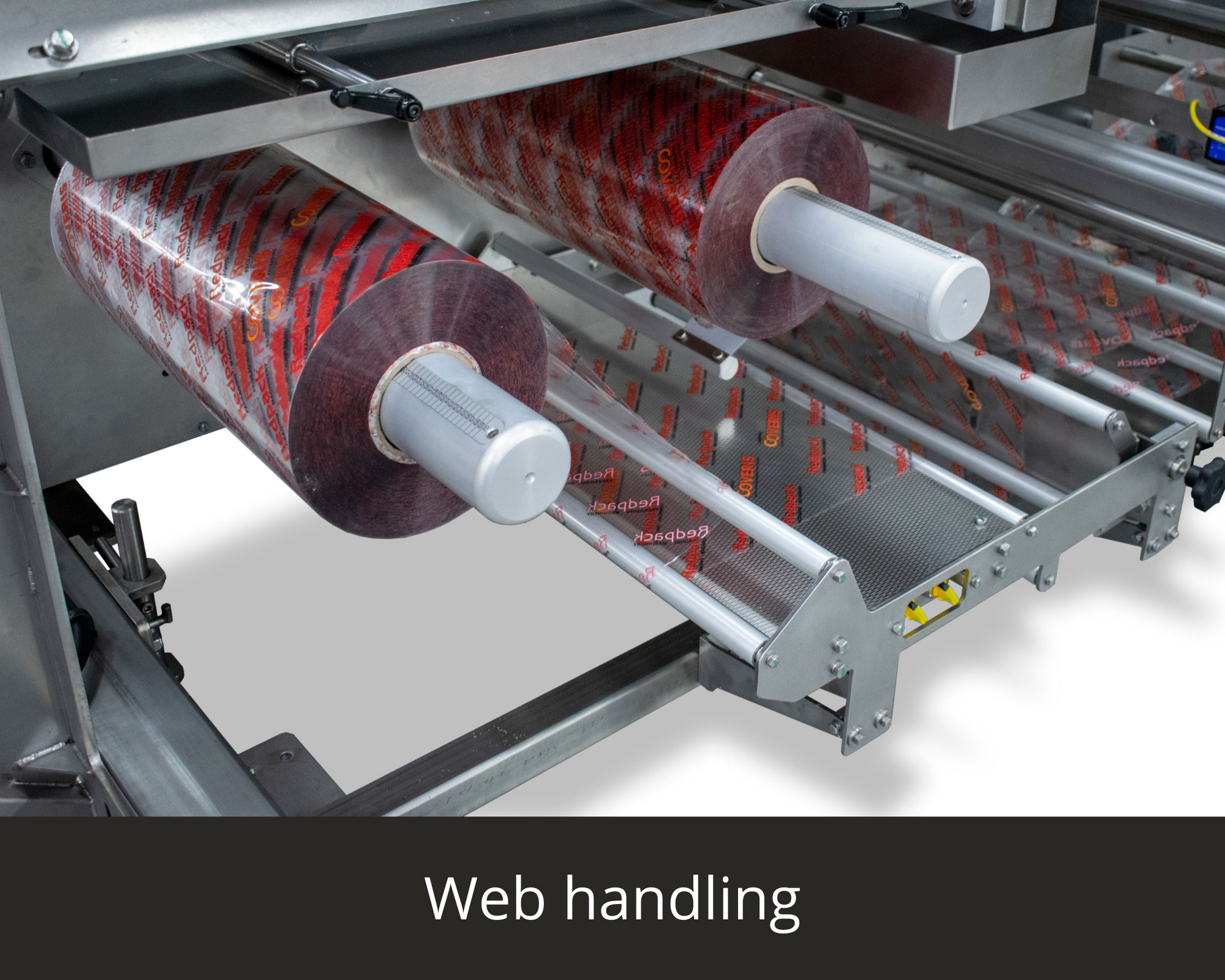

- Quick release pneumatic reel clamping for fine centering adjustment

- Motorized film holder for constant tension film feed to match the film and seam crimp speed

- Reel run-out switch stops the machine when the film runs out

- Hand-wheel adjusted self-centering film fold box for different sized products

- Three sets of seam crimp rollers: first set cold, second set heated, third set film turnover (or four sets of rollers depending on the application)

- Seam crimp release to prevent film melt when the machine stops

- Rotary end crimp with jaw centers to suit product requirement, knife and anvil with fine adjustment for parallelism

- Precision temperature controllers for the seam crimp and end crimp heaters

Visit Redpack at www.redpack.co.uk for more information.

See all Fox Solutions equipment for advanced automation in fresh produce packaging.

Works With

Details

Key Features and Benefits

- Precision engineered components housed in a stainless steel fabrication

- Cantilever design to enhance hygienic cleaning and improve maintenance access

- 24/7 production capability

- Multi-axis electronic drive system with touch screen

- 50 product settings that automatically change the bag length, print registration, end crimp slow down, in feed position, machine

- 20 – 250 packs per min.

- Quick release pneumatic reel clamping for fine centering adjustment

- Motorized film holder for constant tension film feed to match the film and seam crimp speed

- Reel run-out switch stops the machine when the film runs out

- Hand-wheel adjusted self-centering film fold box for different sized products

- Three sets of seam crimp rollers: first set cold, second set heated, third set film turnover (or four sets of rollers depending on the application)

- Seam crimp release to prevent film melt when the machine stops

- Rotary end crimp with jaw centers to suit product requirement, knife and anvil with fine adjustment for parallelism

- Precision temperature controllers for the seam crimp and end crimp heaters

Visit Redpack at www.redpack.co.uk for more information.

See all Fox Solutions equipment for advanced automation in fresh produce packaging.

Downloads

Technical Specs

Electrical requirement

380/440V 50HZ 3Ph N + Earth

Electrical Load

7Kva

Pneumatic requirement

4Bar minimum dry clean air supply

Wrapping materials

OPP, PLA, Heat sealing laminates,

Cold seal

End crimp shaft centre (mm) option

108 126 156 186 201 250

Pack Sizes: (Guide only)

Length (mm): 85-340/100-400/125-490

150-580/160-630/200-790

Width (mm): 20-300 20-300 20-300

20-300 20-300

Height (mm): 1-60 1-90 30-105 30-138

50-150 50-200

(NB The Maximum bag height is dependent upon the required bag width.)

Reel diameter (mm)

300 (max)

Core diameter (mm)

75

Width (mm)

650 / 850

Machine speed

20 – 250ppm (Dependent upon application)

Noise emission

Less than 70dba at 1m

distance, 1.6m above floor

Approx. Machine Dimensions:

Length (m) 4.7

Width (m) 1.1

Height (m) 1.4

Approx. machine wt. 1000Kg

About Company

Redpack Packaging Machinery designs and manufactures Flow Wrapping and Packaging Machinery. Our markets include industries such as fresh produce, pharmaceuticals, snack foods, household products, bakery, greeting cards, gifts and toys, etc. With a brand stretching back over 35 years our flow wrapping design follows tried and tested techniques. Despite this each application brings its own unique requirements for custom designed features.

FAQ

A horizontal top seal flow wrapping machine is a type of packaging equipment designed to create sealed packages for a variety of products. This machine follows the horizontal form-fill-seal (HFFS) process, where packaging material is formed around the product horizontally. The “top seal” aspect refers to the sealing of the package along the top portion. Here are key features and aspects of a horizontal top seal flow wrapping machine:

- Horizontal Form-Fill-Seal (HFFS) Process:

- Like other flow wrappers, the horizontal top seal flow wrapping machine utilizes the HFFS process. It forms a continuous tube of packaging material around the product horizontally.

- Top Seal Mechanism:

- The machine includes a top seal mechanism, which is responsible for sealing the top part of the package. This sealing process ensures that the contents are securely enclosed within the package.

- Product Feeding:

- Products are fed into the machine horizontally for continuous or intermittent packaging. The machine accommodates various product shapes and sizes.

- Packaging Material:

- Flow wrappers work with a range of flexible packaging materials, such as polyethylene, polypropylene, laminates, and more. The choice of material depends on the product and packaging requirements.

- Forming Collar:

- Similar to other flow wrappers, the forming collar shapes the packaging material into a tube around the product. It determines the width and length of the package.

- Sealing System:

- The sealing system is responsible for securely sealing the edges of the packaging material, creating a sealed package. Sealing can be achieved using heat, pressure, or ultrasonic methods, depending on the material and product.

- Adjustable Parameters:

- Operators can adjust various parameters, including film tension, product spacing, and sealing temperature, to optimize the packaging process for different products.

- Cutting Mechanism:

- A cutting mechanism separates individual packages from the continuous material. The cut is typically made after the sealing process.

- Speed and Efficiency:

- Horizontal top seal flow wrapping machines are designed for high-speed packaging, contributing to increased throughput and efficiency in production lines.

- Versatility:

- These machines are versatile and can handle a wide range of products, including bakery items, snacks, confectionery, fresh produce, frozen foods, and more.

- Automatic or Semi-Automatic Operation:

- Horizontal top seal flow wrappers are available in both automatic and semi-automatic configurations. Automatic machines are fully automated, suitable for high-volume production, while semi-automatic machines may require some manual intervention.

- Integration with Other Equipment:

- The machines can be integrated into complete packaging lines, working seamlessly with other equipment such as conveyors, labelers, and inspection systems.

- Tamper-Evident Packaging:

- Horizontal top seal flow wrapping can provide tamper-evident packaging, enhancing the safety and integrity of the packaged products.

- Customization Options:

- Manufacturers can customize horizontal top seal flow wrappers to meet specific product and packaging requirements, including special features or adaptations for unique applications.

A horizontal top seal flow wrapping machine is a type of flow wrapper that includes a top seal mechanism for securely sealing the top part of the packages it creates. It follows the horizontal form-fill-seal process and is suitable for a wide range of products, offering versatility, speed, and efficiency in the packaging process.

A horizontal top seal flow wrapping machine offers several benefits in the packaging industry, providing efficiency, flexibility, and quality in the creation of sealed packages. Here are key advantages of using a horizontal top seal flow wrapping machine:

- Secure Top Sealing:

- The top seal mechanism ensures the secure sealing of the package, providing protection and containment of the packaged product. This contributes to the integrity and safety of the contents.

- Horizontal Form-Fill-Seal (HFFS) Process:

- The HFFS process used by horizontal top seal flow wrappers allows for efficient and continuous packaging. Products are wrapped horizontally, contributing to the speed and effectiveness of the packaging operation.

- High-Speed Operation:

- Horizontal top seal flow wrapping machines are designed for high-speed packaging, facilitating increased throughput and efficiency in production lines. This is particularly beneficial for industries with demanding production requirements.

- Versatility:

- These machines are versatile and can handle a diverse range of products, including bakery items, snacks, confectionery, fresh produce, frozen foods, and more. The adaptability of the machine makes it suitable for various packaging needs.

- Top-Quality Presentation:

- The horizontal top seal flow wrapping process results in packages with a neat and visually appealing presentation. Clear or printed film allows consumers to easily see the contents of the package, enhancing product visibility on retail shelves.

- Tamper-Evident Packaging:

- Horizontal top seal flow wrapping can provide tamper-evident packaging, ensuring the safety and integrity of the packaged products. The sealed top acts as a visible indicator of whether the package has been tampered with.

- Efficient Material Usage:

- The continuous form-fill-seal process minimizes material waste, making the packaging operation more cost-effective. Efficient material usage contributes to overall cost savings for manufacturers.

- Customization Options:

- Manufacturers can customize horizontal top seal flow wrappers to meet specific product and packaging requirements. This includes adjustments for different product sizes, shapes, and packaging styles.

- Integration with Other Equipment:

- Horizontal top seal flow wrapping machines can be integrated into complete packaging lines, working seamlessly with other equipment such as conveyors, labelers, and inspection systems. This integration enhances overall efficiency.

- Reduced Labor Requirements:

- Automatic horizontal top seal flow wrappers require minimal manual intervention, reducing the need for labor in the packaging process. This contributes to labor savings and minimizes the risk of human errors.

- Cost-Effective Packaging Solution:

- The efficiency in material usage, high-speed operation, and reduced labor requirements contribute to the overall cost-effectiveness of horizontal top seal flow wrapping as a packaging solution.

- Hygienic Design:

- Many horizontal top seal flow wrappers are designed with hygiene in mind, featuring easy-to-clean surfaces and meeting industry standards for food and pharmaceutical packaging. This ensures the safety and cleanliness of the packaging environment.

- Wide Range of Applications:

- Horizontal top seal flow wrapping machines find applications in various industries beyond food, including pharmaceuticals, cosmetics, hardware, and more. Their versatility makes them suitable for different packaging needs.

- Quick Changeover and Adjustments:

- Horizontal top seal flow wrappers are designed for quick changeover between different product sizes and types. This flexibility allows manufacturers to adapt to varying packaging requirements.

The benefits of a horizontal top seal flow wrapping machine include secure top sealing, the efficiency of the HFFS process, high-speed operation, versatility, top-quality presentation, tamper-evident packaging, efficient material usage, customization options, integration with other equipment, reduced labor requirements, cost-effectiveness, hygienic design, a wide range of applications, and quick changeover capabilities. These advantages make horizontal top seal flow wrapping machines valuable assets in industries where efficient and high-quality packaging is essential.

A horizontal top seal flow wrapping machine is versatile and can be used to package a variety of food products. Its adaptability makes it suitable for different shapes and sizes of items. Here are examples of types of foods that can be packaged by a horizontal top seal flow wrapping machine:

- Bakery Products:

- Bread loaves

- Buns

- Rolls

- Baguettes

- Snack Foods:

- Potato chips

- Pretzels

- Popcorn

- Crackers

- Confectionery:

- Chocolates

- Candy bars

- Cookies

- Wafers

- Fresh Produce:

- Vegetables (individually or bundled)

- Fruits (individually or bundled)

- Frozen Foods:

- Frozen burritos

- Ice cream bars

- Frozen pizzas

- Dairy Products:

- Cheese blocks

- Cheese slices

- Butter portions

- Meat and Poultry:

- Sausages

- Chicken breasts

- Deli meats

- Fresh Pasta:

- Packaged pasta

- Stuffed pasta

- Health and Energy Bars:

- Protein bars

- Granola bars

- Nutritional bars

- Dried Fruits and Nuts:

- Raisins

- Almonds

- Trail mix

- Cereal and Granola:

- Breakfast cereal bars

- Granola bars

- Beverages:

- Single-serve drink pouches

- Culinary Ingredients:

- Dried herbs

- Spice blends

- Bouillon cubes

- Burgers and Sandwiches:

- Individually wrapped burgers

- Sandwiches

- Popsicles and Ice Cream Novelties:

- Individually wrapped popsicles

- Ice cream sandwiches

- Single-Serve Portions:

- Single-serve portions of condiments

- Single-serve portions of spreads

- Specialty Foods:

- Gourmet chocolates

- Specialty snacks

- Instant Noodles and Soups:

- Individually wrapped instant noodles

- Soup packets

- Pet Treats:

- Dog biscuits

- Cat treats

- Ready-to-Eat Meals:

- Individually packaged ready-to-eat meals

It’s important to note that the adaptability of horizontal top seal flow wrapping machines allows them to handle various shapes and sizes of products. The packaging material used can be adjusted based on the specific requirements of the food product. The clear or printed film used in flow wrapping allows for a visually appealing presentation of the packaged items on retail shelves. Manufacturers can customize these machines to meet the unique packaging needs of different food products.