- Equipment

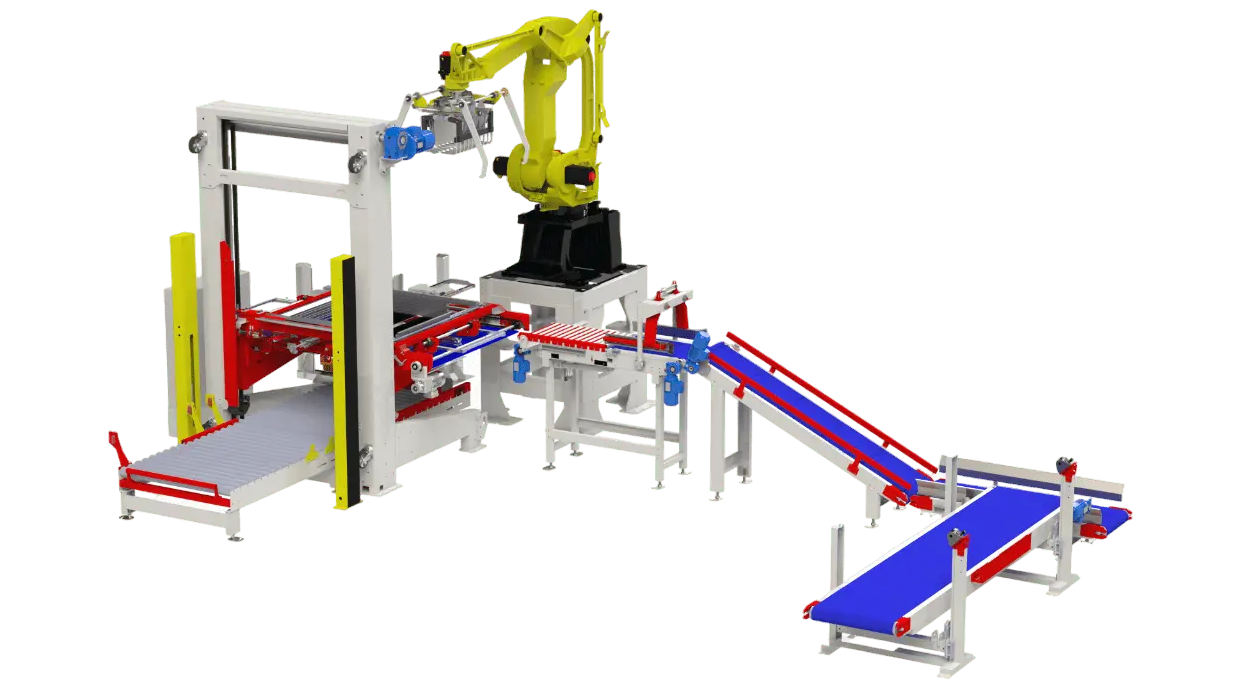

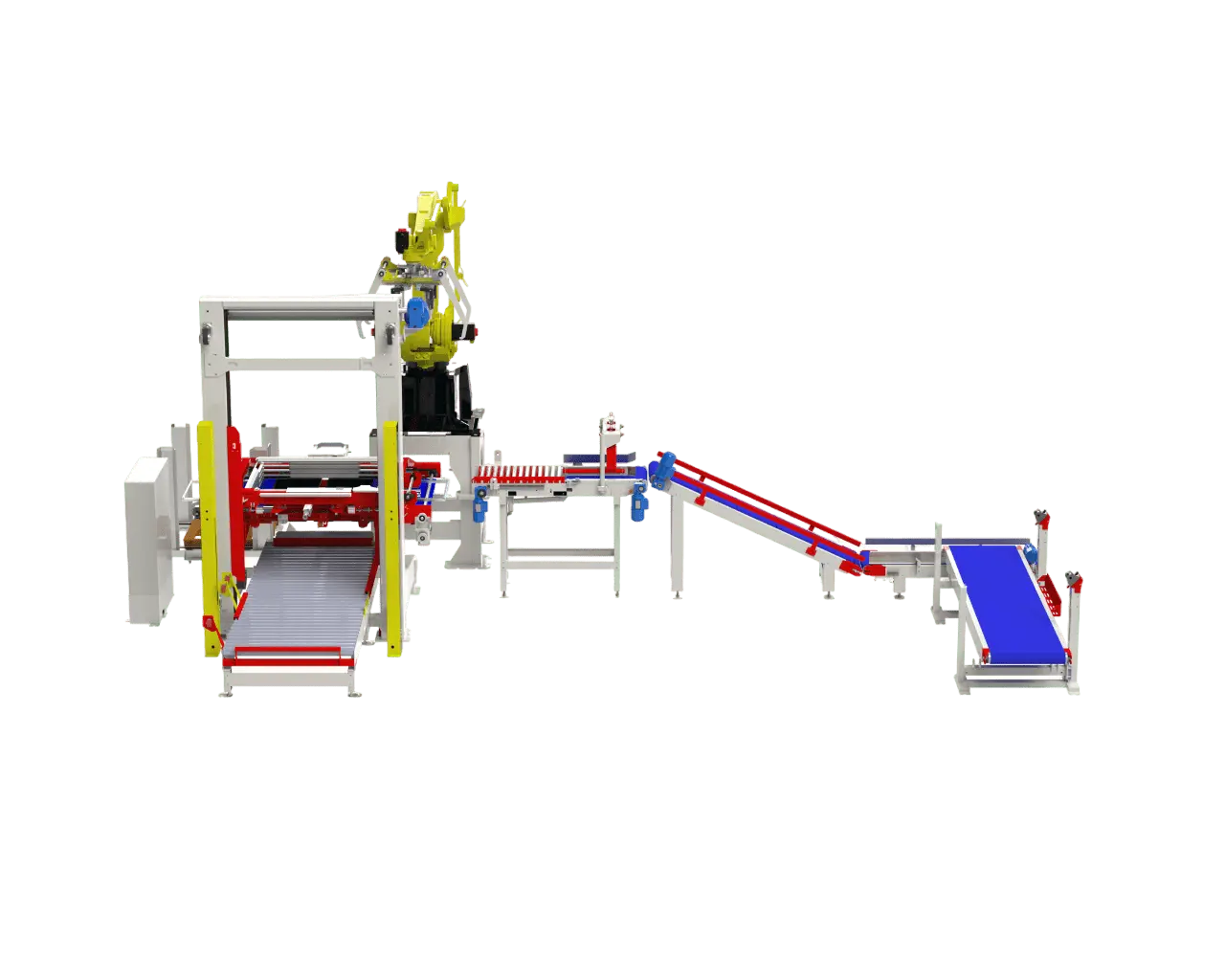

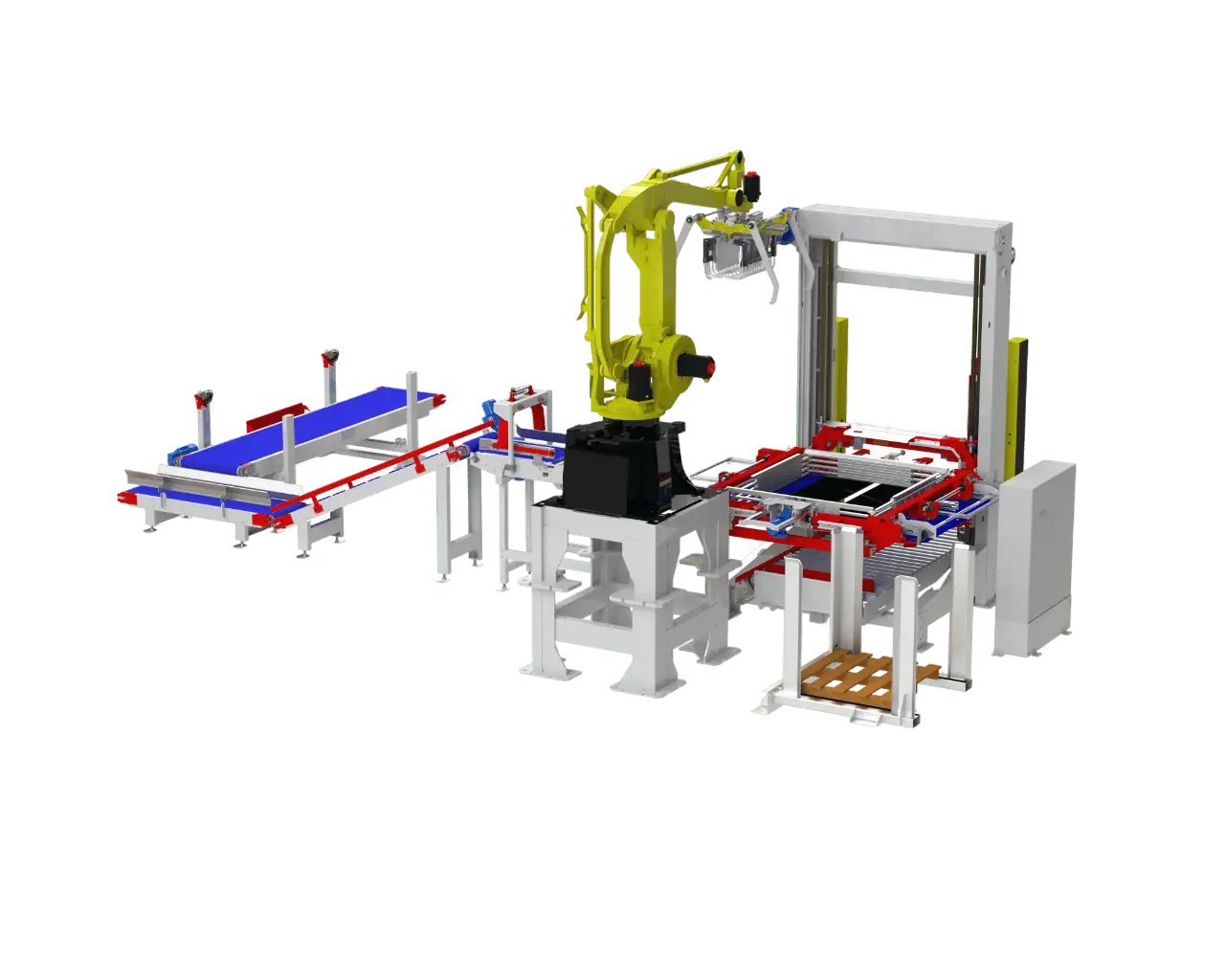

- INTEC PALNB

INTEC PALNB

INTEC PALNB

Details

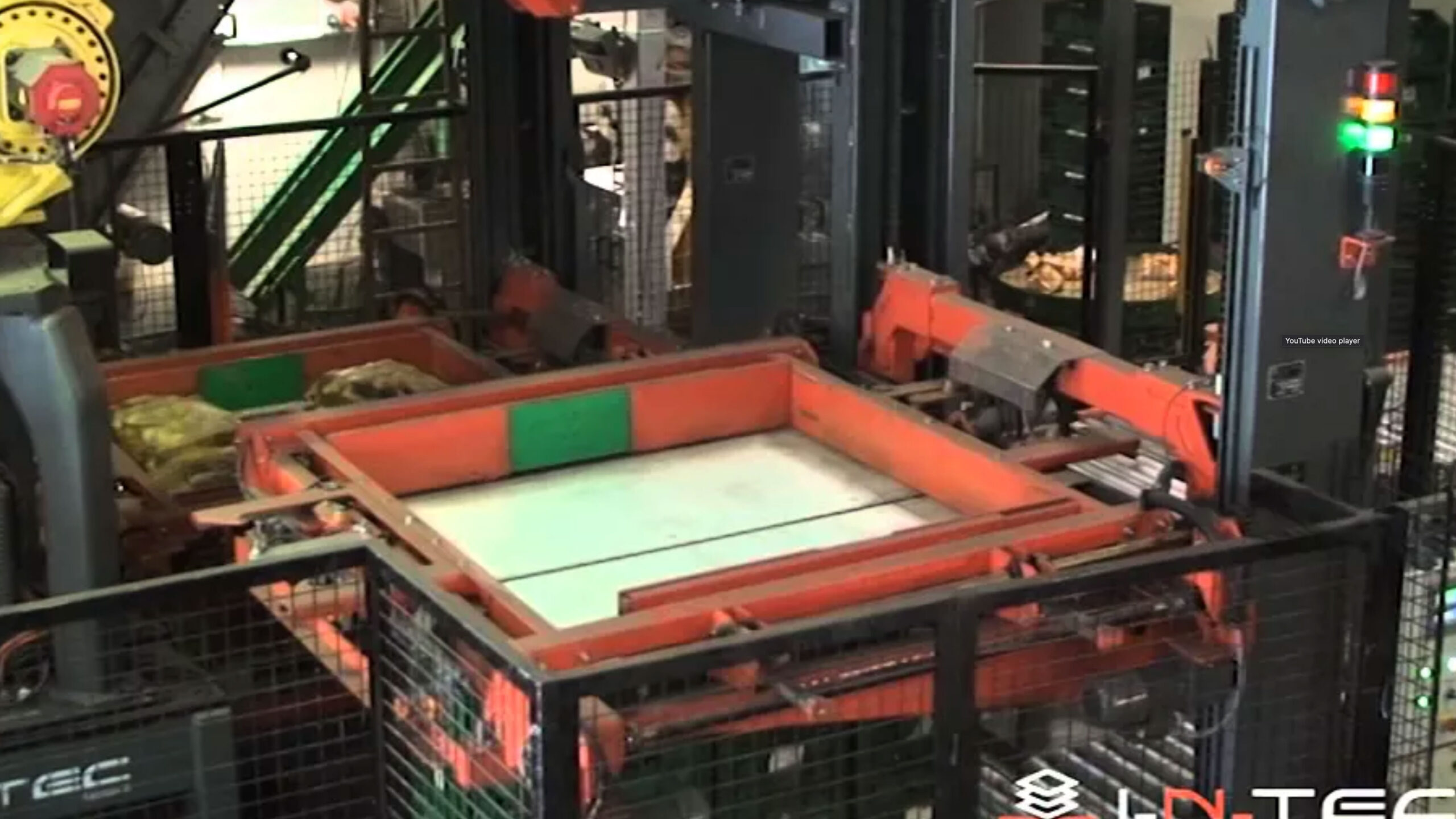

The INTEC PALNB is a fully integrated palletizing system consisting of a robot AND palletizer that is specifically designed for products with great stacking difficulties. This system discharges the product vertically over the pre-layer zone and load assembly inside a mold with frontal and lateral opening capacity. This palletizing system also automatically adapts to different pallet widths. The production capability of the INTEC PALNB palletizer will be affected by the number of maneuvers the robot can carry out.

Key Features and Benefits

- Synchronized opening grip and lateral presses incorporated into the robot

- Mod.Robot P4 pallet robot

- Automatic pneumatic-mechanical stops adjustable to any pallet width and product

- Synchronized gates to prepare the layer

- Synchronized mold opening with pneumatic-mechanical closure

- Pallet extraction rollers

- Lifting platform

Visit Intecpal at www.intecpal.com/en/ for more information.

See all Fox Solutions equipment for advanced automation in fresh produce packaging.

Works With

Details

The INTEC PALNB is a fully integrated palletizing system consisting of a robot AND palletizer that is specifically designed for products with great stacking difficulties. This system discharges the product vertically over the pre-layer zone and load assembly inside a mold with frontal and lateral opening capacity. This palletizing system also automatically adapts to different pallet widths. The production capability of the INTEC PALNB palletizer will be affected by the number of maneuvers the robot can carry out.

Key Features and Benefits

- Synchronized opening grip and lateral presses incorporated into the robot

- Mod.Robot P4 pallet robot

- Automatic pneumatic-mechanical stops adjustable to any pallet width and product

- Synchronized gates to prepare the layer

- Synchronized mold opening with pneumatic-mechanical closure

- Pallet extraction rollers

- Lifting platform

Visit Intecpal at www.intecpal.com/en/ for more information.

See all Fox Solutions equipment for advanced automation in fresh produce packaging.

Downloads

About Company

INTECPAL are specialists in palletizing, bagging and wrapping equipment. Their mission is to design and manufacture the type of machinery that the agro-industrial sector requires, meeting the mechanical, electrical and pneumatic specifications appropriate for each project.

FAQ

A fully integrated palletizing system for packing products on pallets is a comprehensive automation solution designed to efficiently and systematically arrange and stack products onto pallets. This system streamlines the end-of-line packaging process, offering a seamless and automated approach to palletizing various goods. Key components and features of a fully integrated palletizing system include:

- Robotic Palletizing:

- Utilizes industrial robots equipped with grippers or end-of-arm tools to pick up, move, and accurately place products onto pallets. These robots are often programmed for precision and flexibility in handling different product types and pallet configurations.

- Conveyor Systems:

- Conveyor belts or roller conveyors transport products from the production line to the palletizing area. These conveyor systems facilitate a continuous flow of products, optimizing the integration between manufacturing and palletizing processes.

- Pallet Dispenser:

- Automatically dispenses pallets as needed for the palletizing process. This component ensures a steady supply of pallets for the robot to stack products onto.

- Product Orientation and Positioning:

- Systems may include mechanisms for aligning and positioning products in a consistent orientation, making it easier for the robotic palletizer to handle items efficiently.

- Vision Systems:

- Cameras and vision systems are often integrated to recognize products and pallets, ensuring accurate placement and alignment during the palletizing process.

- Customizable End-of-Arm Tools:

- Grippers or end-of-arm tools are adaptable to different product shapes and sizes. These tools can be customized based on the specific requirements of the products being palletized.

- Layer Forming and Configurations:

- The system is capable of creating specific layer patterns or configurations on the pallet, optimizing space utilization and stability during transport.

- Palletizing Software:

- Advanced software controls the operation of the robotic palletizer, managing product patterns, pallet configurations, and overall system coordination. This software may also include features for programming, monitoring, and adjusting the palletizing process.

- Safety Features:

- Integrated safety features ensure the protection of both operators and the equipment. This may include sensors, emergency stop mechanisms, and safety barriers.

- Palletizing Efficiency:

- The system is designed for high-speed and high-precision palletizing, contributing to increased production efficiency and throughput.

- Integration with Warehouse Management Systems (WMS):

- Integration with WMS allows for real-time data exchange, inventory tracking, and improved coordination between production and warehouse processes.

- User-Friendly Interface:

- The system typically features a user-friendly interface for operators to monitor, control, and troubleshoot the palletizing process. This interface may be accessible through a touchscreen panel or a computer interface.

- Flexibility and Scalability:

- The fully integrated palletizing system is designed to be flexible and scalable to accommodate changes in production requirements and handle a variety of products.

- Energy Efficiency:

- Some systems incorporate energy-efficient components and programming to optimize energy consumption during operation.

- Remote Monitoring and Maintenance:

- Remote monitoring capabilities allow for real-time monitoring of system performance and may include remote maintenance features for quick issue resolution.

- Pallet Stretch Wrapping:

- In some cases, the system may be integrated with pallet stretch wrapping equipment to complete the packaging process before shipping.

A fully integrated palletizing system enhances the end-of-line packaging process by automating the stacking of products on pallets, increasing efficiency, reducing labor costs, and ensuring precision and consistency in pallet configurations.

A fully integrated palletizing system for packing products on pallets offers several benefits, streamlining the end-of-line packaging process and enhancing overall efficiency in manufacturing and distribution. Here are key advantages associated with the implementation of such a system:

- Increased Efficiency:

- Automation of the palletizing process significantly increases overall efficiency by reducing manual labor requirements. The system can operate at high speeds, ensuring faster and more consistent palletization.

- Labor Cost Savings:

- Automated palletizing reduces dependency on manual labor, leading to cost savings in terms of labor expenses. Operators can be redeployed to more skilled or strategic tasks within the production facility.

- Consistent Product Handling:

- The system ensures consistent and precise handling of products during palletization. This consistency contributes to the quality and uniformity of palletized loads, reducing the risk of errors in stacking patterns.

- Optimized Pallet Configurations:

- The system can be programmed to optimize pallet configurations, ensuring efficient use of space and minimizing the risk of product damage during transport. This optimization is crucial for reducing shipping costs and maximizing storage capacity.

- Flexibility in Product Handling:

- Automated systems are often designed to handle a variety of product types, shapes, and sizes. This flexibility allows manufacturers to adapt to changing product lines and packaging requirements.

- Higher Throughput:

- The automated nature of the palletizing system enables higher throughput, meeting the demands of fast-paced production environments. Increased throughput contributes to overall production capacity and responsiveness to market demands.

- Reduction in Manual Errors:

- Automation reduces the likelihood of errors associated with manual palletizing, such as misplacements or misalignments. This leads to improved accuracy in the assembly of pallet loads.

- Enhanced Safety:

- Integrated safety features in automated palletizing systems contribute to a safer working environment. Sensors, emergency stop mechanisms, and safety barriers help prevent accidents and injuries.

- Real-time Monitoring and Control:

- Many systems include monitoring and control features, allowing operators to oversee the palletizing process in real-time. This capability facilitates quick response to issues, minimizing downtime and optimizing system performance.

- Integration with Warehouse Management Systems (WMS):

- Integration with WMS enables seamless communication between the palletizing system and broader warehouse operations. This integration improves inventory tracking, order fulfillment, and overall logistics management.

- Adaptability to Production Changes:

- Fully integrated palletizing systems are designed to be adaptable to changes in production requirements. This adaptability ensures that the system can accommodate new products, packaging formats, or production line configurations.

- Improved Product Traceability:

- Integration with tracking and tracing systems enhances product traceability throughout the supply chain. This is particularly important for compliance with regulatory standards and addressing product recalls if necessary.

- Energy Efficiency:

- Some systems incorporate energy-efficient components and programming, contributing to reduced energy consumption during operation. This aligns with sustainability initiatives and environmental considerations.

- Enhanced Product Presentation:

- The systematic and automated palletizing process contributes to the neat and organized presentation of products on pallets. This can enhance the overall visual appeal of palletized loads, especially for retail-ready displays.

A fully integrated palletizing system offers benefits such as increased efficiency, labor cost savings, consistent product handling, optimized pallet configurations, and enhanced safety. These advantages make automated palletizing systems a valuable investment for manufacturers seeking to improve their packaging processes and overall supply chain operations.

A fully integrated palletizing system is designed to handle a wide range of products, including those that may be challenging to stack manually. The system’s flexibility, precision, and adaptability make it suitable for managing products with varying shapes, sizes, and characteristics. Here are examples of products that are often considered difficult to stack but can be effectively handled by a well-designed fully integrated palletizing system:

- Irregular-Shaped Items:

- Products with irregular shapes, such as odd-sized or asymmetrical packaging, can be challenging to stack manually. A robotic palletizing system can adapt its grip and placement strategies to handle irregular-shaped items with precision.

- Bags and Sacks:

- Loose bags or sacks, particularly those containing granular or powdery materials, are prone to shifting and collapsing during manual stacking. An automated system can handle bags of various sizes and materials, ensuring a stable and well-organized pallet load.

- Cartons with Varying Dimensions:

- Cartons with different dimensions, varying heights, or lightweight construction can pose challenges for manual stacking. A robotic palletizer can accurately assess and stack cartons with diverse dimensions without compromising stability.

- Unstable or Fragile Products:

- Fragile items or products with unstable structures that are prone to breakage or deformation can be stacked gently and precisely by a robotic system. The system’s sensors and adaptive grippers ensure delicate handling to prevent damage.

- Mixed-Product Pallets:

- Palletizing multiple products with different sizes and shapes on the same pallet can be complex for manual operators. A fully integrated system can efficiently handle mixed-product palletizing, adapting to various SKU configurations.

- Fresh Produce:

- Fruits and vegetables with irregular shapes, sizes, and delicate skins can be challenging to stack manually without causing damage. Automated systems equipped with soft grippers and advanced vision systems can handle fresh produce with care.

- Beverage Cases:

- Cases of bottled or canned beverages can be challenging to stack manually, especially when dealing with varying bottle sizes or packaging configurations. A robotic palletizer ensures precise and stable stacking of beverage cases.

- Bulk Items or Large Bags:

- Large bags or bulk items, such as pet food, fertilizer, or seeds, may be difficult to stack manually due to their weight and size. Automated systems are equipped to handle heavy loads efficiently, optimizing palletization in industries like agriculture and manufacturing.

- Difficult-to-Handle Packaging Materials:

- Packaging materials that are slippery, prone to sticking, or challenging to grip manually can be efficiently handled by a robotic palletizing system. The system’s adaptable grippers and sensors ensure secure handling.

- Frozen Food Products:

- Frozen food items with irregular shapes or varying sizes, such as frozen pizzas or irregularly shaped frozen vegetables, can be stacked with precision using a robotic palletizing system designed for cold environments.

- Automotive Parts:

- Irregularly shaped or heavy automotive parts may be challenging to stack manually due to their weight and bulk. Robotic palletizing systems with advanced gripping mechanisms can handle these parts effectively.

The adaptability and precision of a fully integrated palletizing system make it well-suited for handling products that pose challenges for manual stacking. By leveraging robotics, advanced sensors, and intelligent programming, these systems ensure efficient, stable, and safe palletization across a diverse range of products and industries.