- Equipment

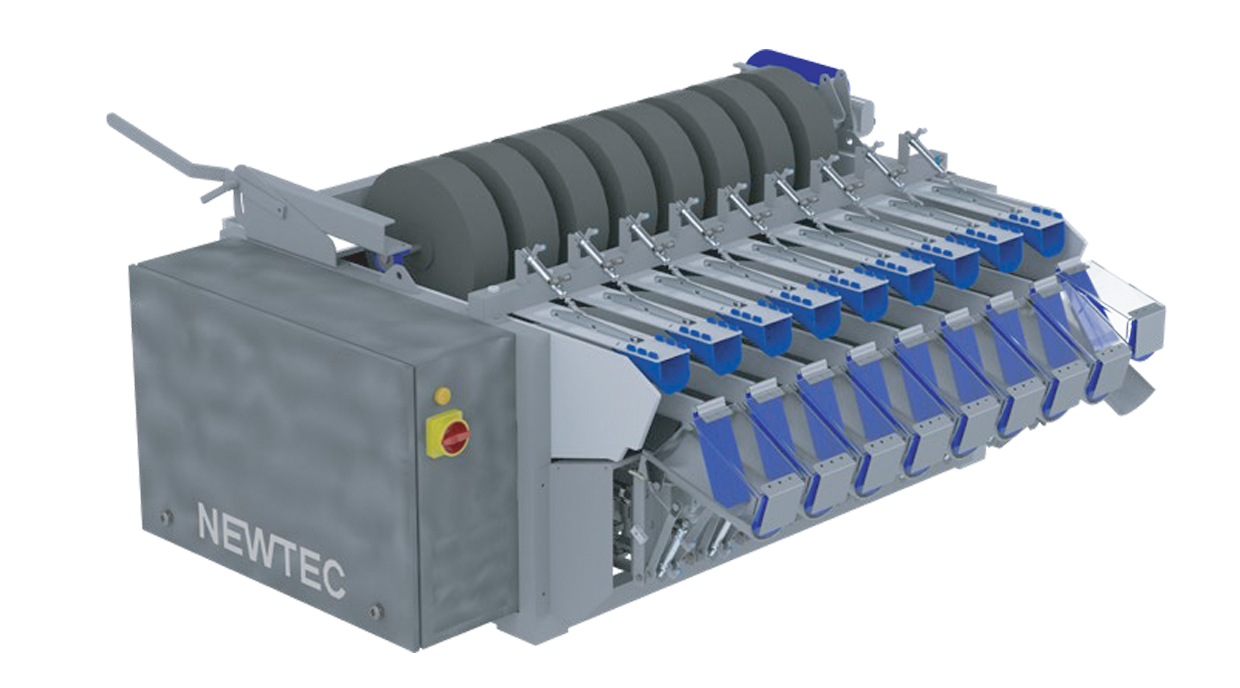

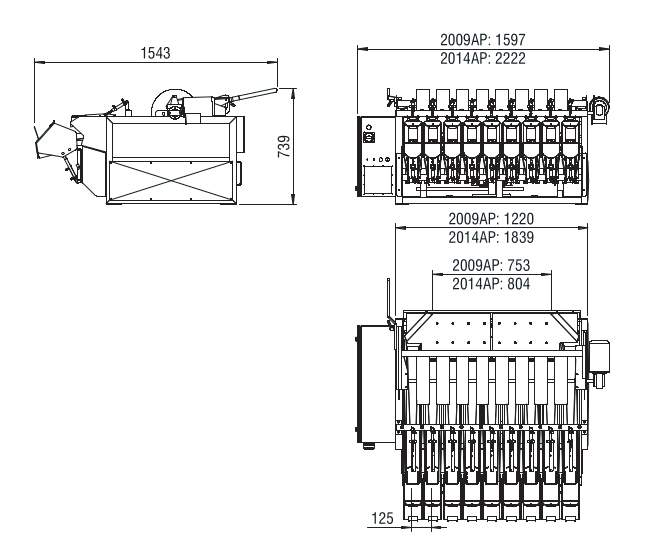

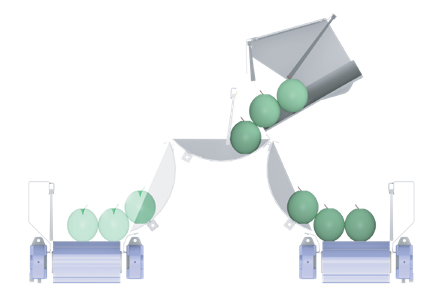

- NEWTEC 2009A

NEWTEC 2009A

NEWTEC 2009A

Details

Key Features and Benefits

- Full stainless steel construction

- 9 weigh-heads

- Up to 24 portions per minute

- Easy access for cleaning

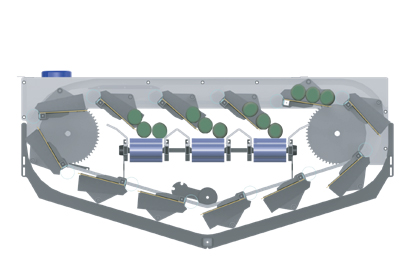

- Gentle rotating brushes prevent bridging across infeed channels

- Fast configuration of target weight

- Fully automatic infeed control

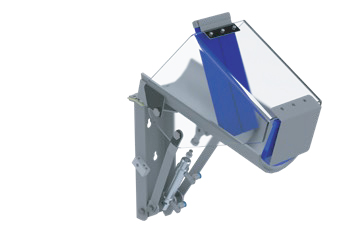

- Available with extended weigh-heads for large portions

- Use with: Apples, Pears, and Tomatoes

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions Weighers for advanced automation in fresh produce packaging.

Works With

Pears

Pears

Details

Key Features and Benefits

- Full stainless steel construction

- 9 weigh-heads

- Up to 24 portions per minute

- Easy access for cleaning

- Gentle rotating brushes prevent bridging across infeed channels

- Fast configuration of target weight

- Fully automatic infeed control

- Available with extended weigh-heads for large portions

- Use with: Apples, Pears, and Tomatoes

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions Weighers for advanced automation in fresh produce packaging.

Downloads

About Company

Newtec is a leading manufacturer of weighing, packing and sorting machinery primarily for the fruit and vegetable industry. With more than 15,000 successful installations over the last 40 years, we have maintained our position as a reputable worldwide company. At Newtec, we pride ourselves on the ability to design solutions that meet your specific needs by combining our machines and the latest technology in new and innovative ways.

We have a reputation for developing, engineering and building high-quality, high-performance machines that our customers rely on.

We focus on building successful long-term relationships with our customers. Understanding your business and the potential challenges it faces is a critical step in order to deliver solutions that make an impactful difference.

FAQ

An Automatic Weigher for produce, such as apples, carrots, parsnips, and tomatoes, is a specialized weighing machine designed for the efficient and accurate measurement of the weight of individual or grouped pieces of fresh produce. These machines are commonly used in the food industry, particularly in the fruit and vegetable packing processes. Here are the key features and functions of an automatic weigher for produce:

- Precision Weighing: These machines are equipped with accurate weighing mechanisms that can measure the weight of each piece of produce with high precision. This is crucial for ensuring consistency in packaging and meeting weight specifications.

- High Speed: Automatic weighers are designed to operate at high speeds, facilitating efficient and rapid weighing of a large volume of produce. This is especially important in industries where there is a need for quick and continuous processing.

- Conveyor System: Typically, these machines incorporate a conveyor system that transports the produce to the weighing station. The conveyor ensures a steady flow of items, allowing for continuous and automated weighing.

- Sorting and Grading: Some automatic weighers are equipped with sorting and grading capabilities. After weighing, the machine may categorize the produce based on predefined weight ranges or quality criteria.

- User-Friendly Interface: The machines often have a user-friendly interface that allows operators to set weight parameters, monitor the weighing process, and make adjustments as needed.

- Integration with Packaging Equipment: Automatic weighers are often integrated into packaging lines. They can work seamlessly with other equipment, such as vertical form-fill-seal machines or horizontal flow wrapping machines, to ensure that the produce is packaged accurately according to the desired weight.

- Adjustable Parameters: Operators can often adjust various parameters, such as target weights, to accommodate different types and sizes of produce.

- Gentle Handling: These machines are designed to handle delicate produce with care, minimizing the risk of damage during the weighing process.

- Hygiene and Food Safety: Many automatic weighers for produce are constructed using materials that meet hygiene and food safety standards. They are designed to be easy to clean to maintain a sanitary processing environment.

- Customization: Depending on the specific needs of the application, these machines may offer customization options to adapt to different types of produce and packaging requirements.

Automatic weighers for produce play a crucial role in optimizing the efficiency of the packing process, reducing labor costs, and ensuring that products are accurately and consistently weighed before reaching the market.

Using an Automatic Weigher for produce, such as apples, carrots, parsnips, and tomatoes, offers several benefits in the food processing and packaging industry. Here are some key advantages:

- Accuracy and Consistency: Automatic weighers provide precise and consistent weight measurements for each piece of produce. This ensures that packaged products meet quality standards and regulatory requirements.

- Efficiency and Speed: These machines operate at high speeds, facilitating rapid weighing and processing of large quantities of produce. Increased efficiency contributes to higher overall productivity in the packaging line.

- Labor Savings: Automating the weighing process reduces the reliance on manual labor, leading to cost savings and increased efficiency. This is particularly beneficial in industries where large volumes of produce need to be processed.

- Customization: Automatic weighers often offer flexibility and customization options. Operators can adjust parameters to accommodate different sizes, varieties, and weight ranges of produce, making the machine versatile for various types of fruits and vegetables.

- Integration with Packaging Equipment: These weighers are designed to seamlessly integrate with other packaging equipment, such as bagging machines or sorting systems. This integration ensures a smooth and continuous flow of produce through the entire packaging process.

- Reduced Product Giveaway: Accurate weighing helps minimize product giveaway, ensuring that each packaged item contains the specified amount of produce. This is crucial for controlling costs and maintaining profitability.

- Sorting and Grading: Some automatic weighers include sorting and grading functionalities. This allows the machine to categorize produce based on predefined criteria, helping to meet specific quality standards and customer preferences.

- Data Collection and Reporting: Many modern automatic weighers are equipped with data collection and reporting features. This data can be used for quality control, traceability, and overall process optimization.

- Hygienic Design: Automatic weighers are often constructed with materials and designs that adhere to hygiene and food safety standards. Easy-to-clean surfaces and sanitary construction contribute to maintaining a clean processing environment.

- Gentle Handling of Produce: These machines are designed to handle delicate produce with care, minimizing the risk of bruising or damage during the weighing process. This is essential for preserving the quality and appearance of the final packaged products.

- Adaptability to Various Products: Automatic weighers can be adjusted to handle a variety of produce types, sizes, and shapes. This adaptability makes them suitable for a diverse range of fruits and vegetables.

The use of Automatic Weighers for produce brings efficiency, accuracy, and flexibility to the packaging process, ultimately benefiting both producers and consumers by delivering consistently weighed and high-quality products.

An Automatic Weigher is a versatile machine used in various industries, particularly in the food sector, to accurately weigh and portion different types of products. Here are examples of foods that can be weighed by an Automatic Weigher:

- Fresh Produce:

- Apples

- Bananas

- Grapes

- Tomatoes

- Berries

- Citrus fruits (oranges, lemons)

- Leafy greens

- Root Vegetables:

- Carrots

- Potatoes

- Onions

- Parsnips

- Beets

- Snack Foods:

- Potato chips

- Pretzels

- Popcorn

- Nuts

- Confectionery:

- Chocolates

- Candies

- Gummies

- Bakery Products:

- Bread

- Rolls

- Pastries

- Cookies

- Dairy Products:

- Cheese blocks or slices

- Butter

- Yogurt

- Meat and Poultry:

- Chicken breasts

- Pork chops

- Beef steaks

- Sausages

- Seafood:

- Fish fillets

- Shrimp

- Frozen Foods:

- Frozen vegetables

- Frozen fruits

- Frozen meals

- Cereal and Grains:

- Rice

- Pasta

- Cereal

- Dried Fruits and Nuts:

- Raisins

- Almonds

- Walnuts

- Pre-packaged Meals:

- Ready-to-eat meals

- Convenience foods

- Beverages:

- Coffee beans

- Tea leaves

- Pet Food:

- Kibble and dry pet food

- Specialty Foods:

- Herbs and spices

- Specialty grains (quinoa, couscous)

- Health Foods:

- Protein bars

- Granola bars

- Baby Foods:

- Jars of baby food

- Pouches of baby food

These examples showcase the versatility of Automatic Weighers, which can handle a wide range of food products with different shapes, sizes, and textures. The adaptability of these machines makes them valuable in various food processing and packaging operations where accurate weighing is critical.