- Equipment

- NEWTEC Celox-C-UHD

NEWTEC Celox-C-UHD

NEWTEC Celox-C-UHD

Details

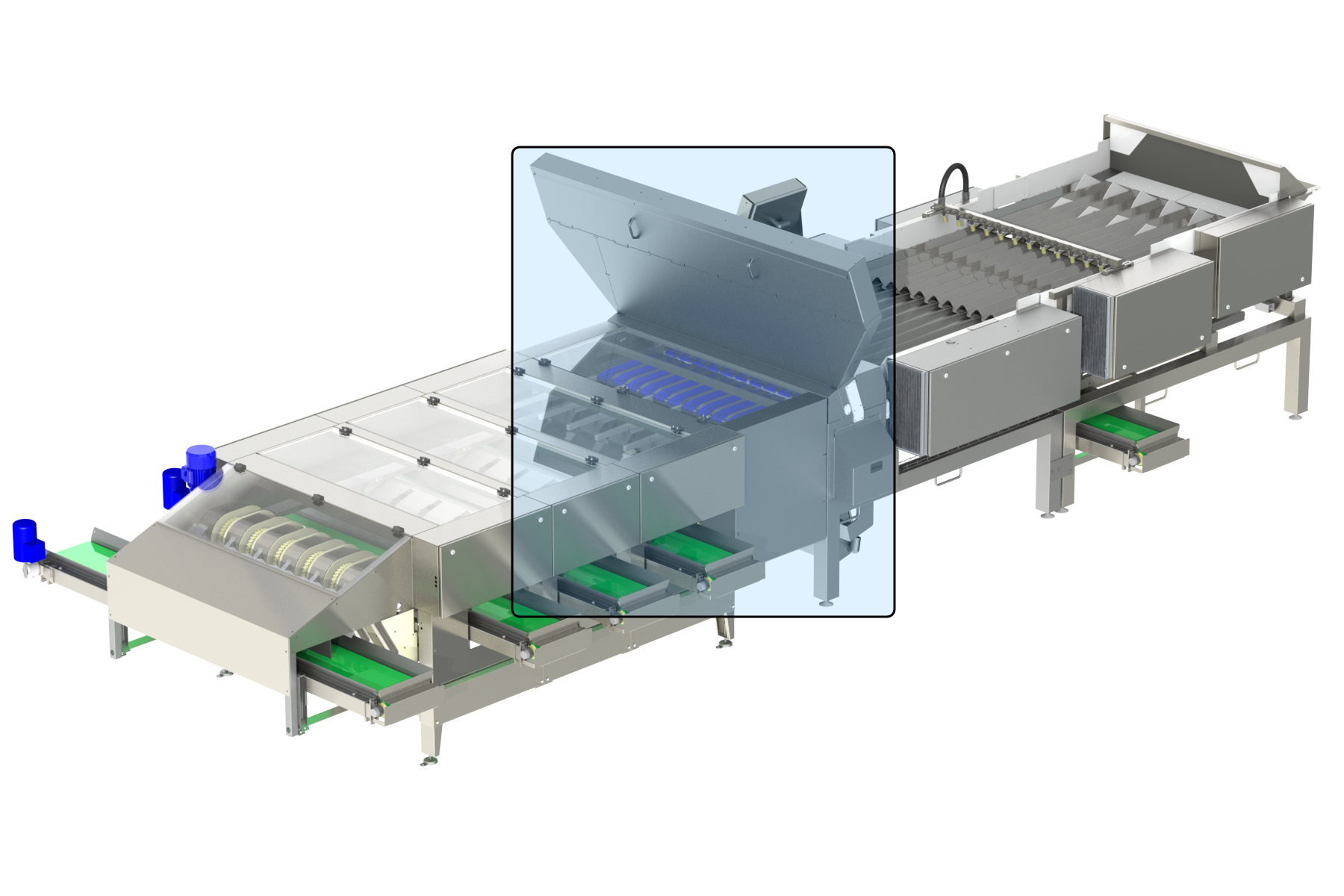

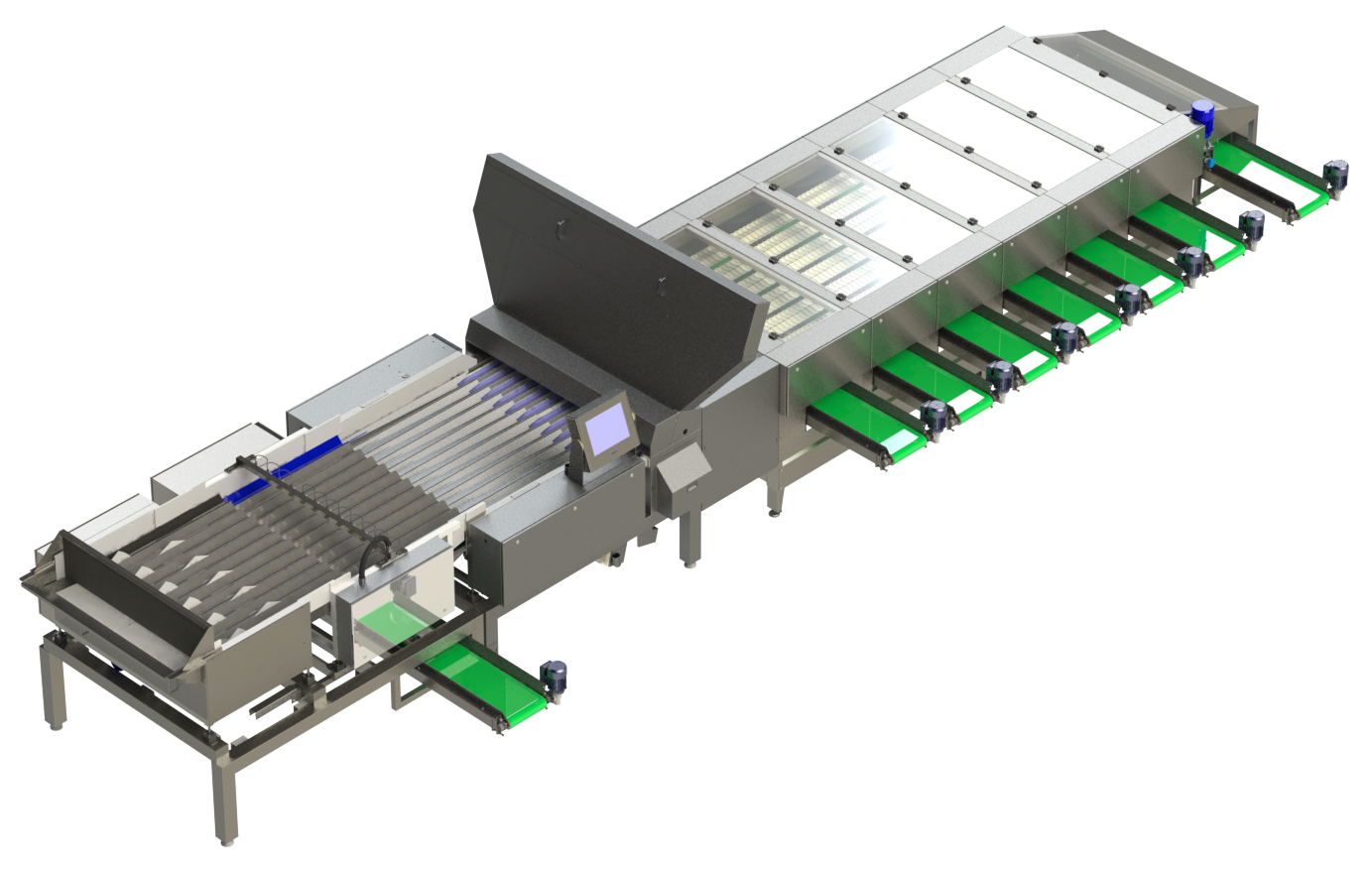

The Newtec Celox-C-UHD is a high-performance optical sorting machine designed to sort washed carrots by size, shape, and quality in a single-stage process. Available with 4, 8, or 12 lanes, it eliminates the need for pre-grading, minimizes manual labor, and ensures consistent quality and high throughput.

Key Features and Benefits

Precision Sorting for Maximum Efficiency

- Simultaneously sorts up to 13 product categories, optimizing processing time.

- Instantly customizable sorting criteria to meet changing demands.

- Accurate selection of high-value products, maximizing profitability.

Advanced Technology for Superior Performance

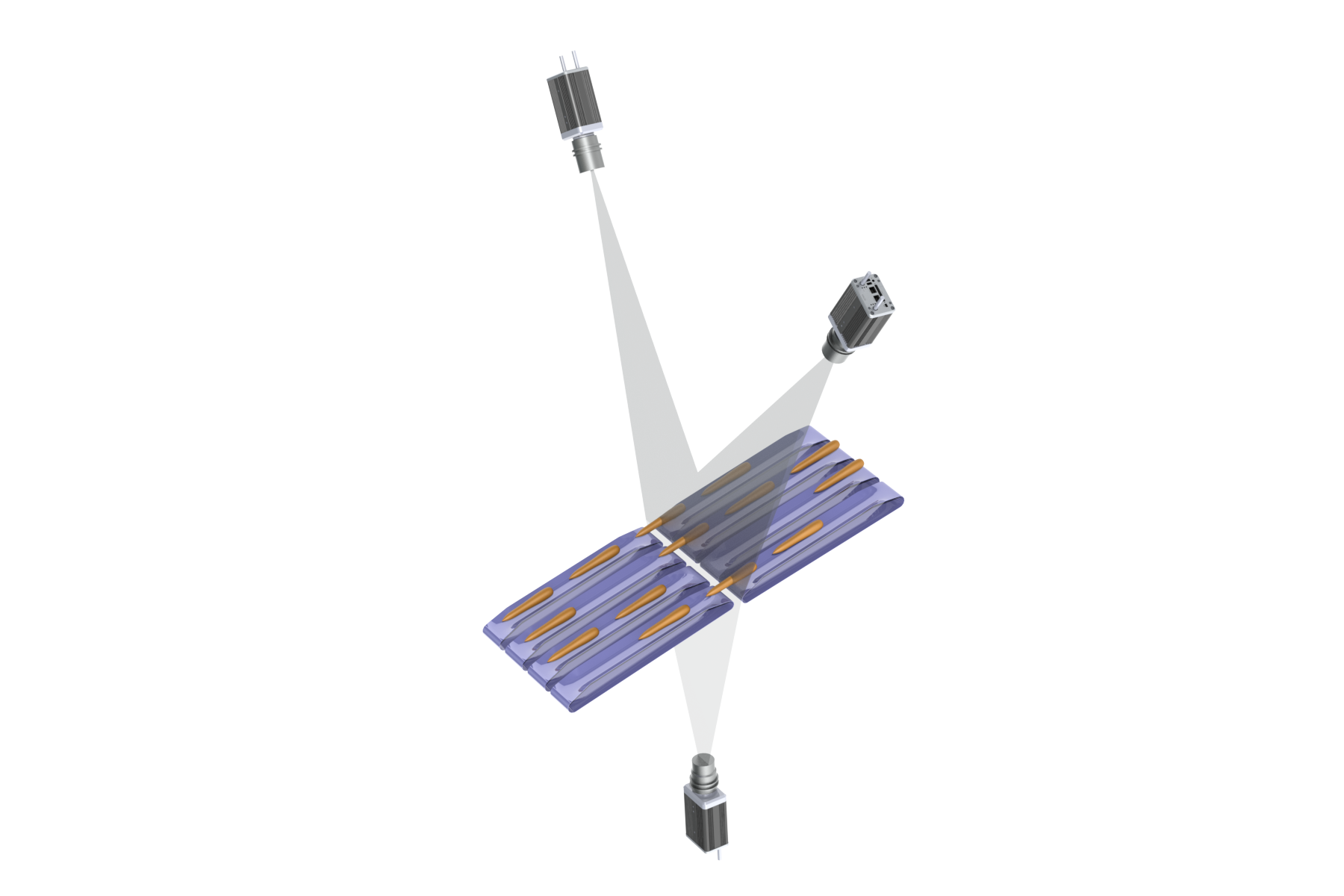

- High-end UHD cameras from Q Technology ensure precise color consistency.

- New generation camera platform enhances sorting accuracy.

- No need for mechanical pre-grading, reducing operational steps and costs.

Optimized Product Handling and Data Integration

- Gentle product handling maintains carrot integrity and reduces waste.

- Real-time product data collection through Newtec WebServices provides valuable insights.

- Data can be integrated into business IT systems for enhanced production analysis.

Flexible and Scalable Design

- Modular design supports future expansion, allowing sorting of up to 16 categories/outlets.

- Compact footprint with high output, ideal for optimizing space.

- Robust stainless-steel construction ensures durability in demanding environments.

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions optical sorters and graders for innovative solutions tailored to your processing needs.

Works With

Details

The Newtec Celox-C-UHD is a high-performance optical sorting machine designed to sort washed carrots by size, shape, and quality in a single-stage process. Available with 4, 8, or 12 lanes, it eliminates the need for pre-grading, minimizes manual labor, and ensures consistent quality and high throughput.

Key Features and Benefits

Precision Sorting for Maximum Efficiency

- Simultaneously sorts up to 13 product categories, optimizing processing time.

- Instantly customizable sorting criteria to meet changing demands.

- Accurate selection of high-value products, maximizing profitability.

Advanced Technology for Superior Performance

- High-end UHD cameras from Q Technology ensure precise color consistency.

- New generation camera platform enhances sorting accuracy.

- No need for mechanical pre-grading, reducing operational steps and costs.

Optimized Product Handling and Data Integration

- Gentle product handling maintains carrot integrity and reduces waste.

- Real-time product data collection through Newtec WebServices provides valuable insights.

- Data can be integrated into business IT systems for enhanced production analysis.

Flexible and Scalable Design

- Modular design supports future expansion, allowing sorting of up to 16 categories/outlets.

- Compact footprint with high output, ideal for optimizing space.

- Robust stainless-steel construction ensures durability in demanding environments.

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions optical sorters and graders for innovative solutions tailored to your processing needs.

Downloads

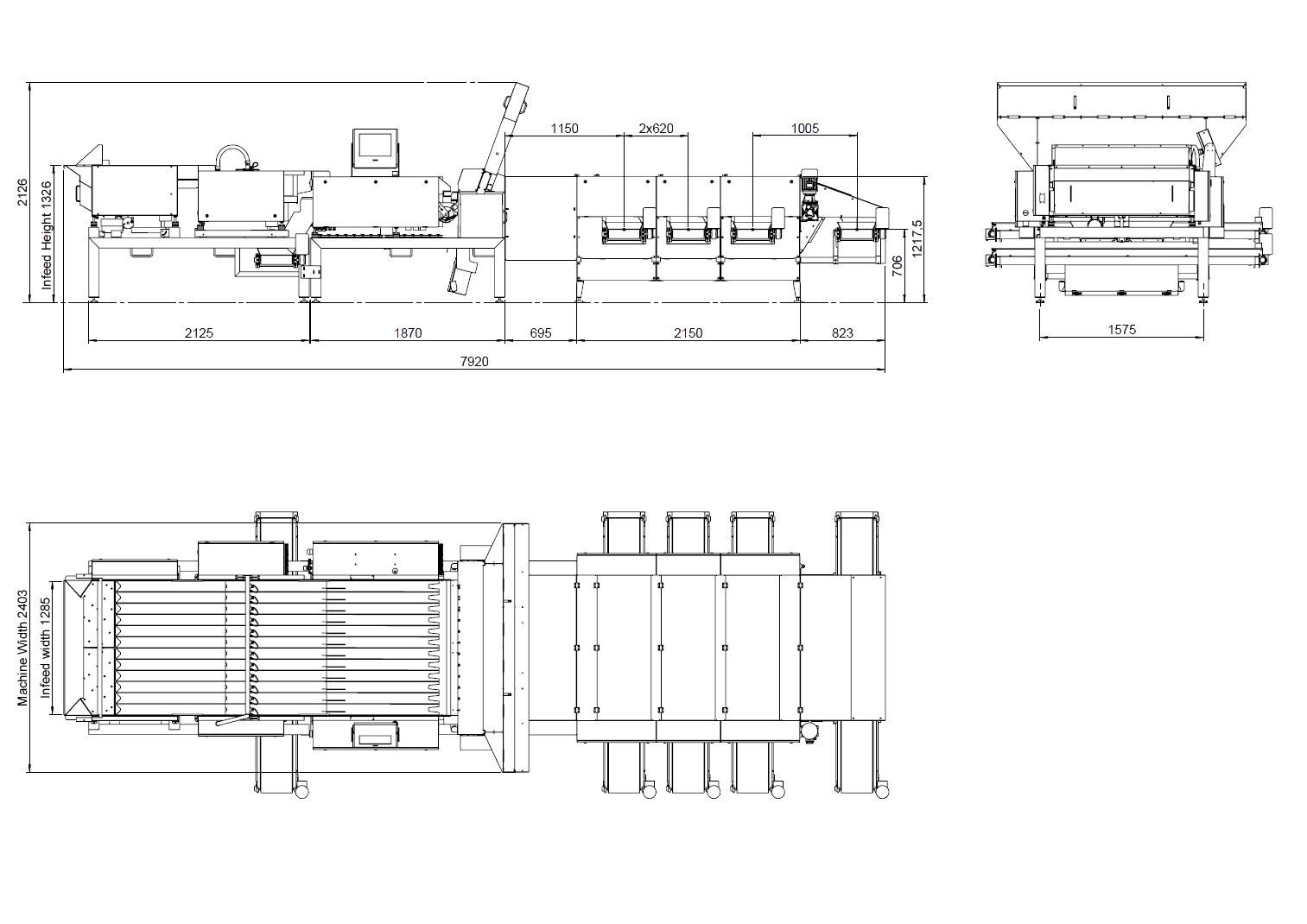

Technical Specs

Capacity

4 lanes : up to 40,000 carrots/h

8 lanes: up to 80,000 carrots/h

12 lanes: up to 120,000 carrots/h

Electrical requirement

3x400V+N+PE, 20A

Environment

5°C – 40°C/41°F – 104°F

Weight

From 1200 kg – 4000 kg

About Company

Newtec is a leading manufacturer of weighing, packing and sorting machinery primarily for the fruit and vegetable industry. With more than 15,000 successful installations over the last 40 years, we have maintained our position as a reputable worldwide company. At Newtec, we pride ourselves on the ability to design solutions that meet your specific needs by combining our machines and the latest technology in new and innovative ways.

We have a reputation for developing, engineering and building high-quality, high-performance machines that our customers rely on.

We focus on building successful long-term relationships with our customers. Understanding your business and the potential challenges it faces is a critical step in order to deliver solutions that make an impactful difference.

FAQ

An optical sorting machine for carrots is a specialized equipment designed specifically for sorting carrots based on their visual characteristics. This type of machine utilizes advanced optical technology, cameras, and sensors to inspect each carrot as it moves through the sorting process. The primary goal is to identify and separate carrots based on predetermined criteria such as size, shape, color, and the presence of defects.

Here are key features and functions of an optical sorting machine for carrots:

- Color Sorting: The machine can effectively sort carrots based on their color. This is particularly important for ensuring consistency in the final product and meeting market preferences.

- Size Sorting: Carrots come in various sizes, and an optical sorting machine can categorize them based on their dimensions. This helps in creating uniform batches for packaging.

- Defect Detection: The optical system is capable of detecting defects or irregularities in carrots, such as blemishes, rot, or misshapen portions. Defective carrots can be automatically separated from the good ones, contributing to improved product quality.

- High-Speed Operation: Optical sorters for carrots are designed to operate at high speeds, allowing for efficient and continuous sorting in large-scale production environments.

- Customizable Settings: Operators can often customize sorting parameters to adapt the machine to different varieties of carrots and specific quality requirements. This flexibility is crucial in accommodating variations in the characteristics of the produce.

- Gentle Handling: The design of the optical sorting machine takes into consideration the delicate nature of carrots. The sorting process is engineered to handle carrots gently, minimizing the risk of damage during sorting.

- Integration with Packaging Lines: Optical sorting machines are often integrated into larger carrot processing and packaging lines. This integration allows for a seamless transition from sorting to subsequent stages in the production process.

- Reject System: Defective or off-spec carrots are typically separated and removed from the main product stream using a reject system. This ensures that only high-quality carrots proceed to the next stages of processing.

- Data Collection and Reporting: Some modern optical sorting machines provide data collection and reporting features. This data can be valuable for quality control, traceability, and process optimization.

- Adaptability to Different Carrot Varieties: Optical sorters can be adjusted to handle various carrot varieties, including different colors and shapes.

An optical sorting machine for carrots plays a crucial role in streamlining the carrot processing industry by improving efficiency, ensuring product quality, and reducing waste. Its ability to make rapid and accurate decisions based on visual characteristics makes it an essential component in carrot sorting and packaging operations.

An optical sorting machine for carrots offers several benefits in the carrot processing industry, contributing to improved efficiency, enhanced product quality, and reduced waste. Here are key advantages of using an optical sorting machine for carrots:

- Increased Sorting Accuracy: Optical sorting machines provide high-precision sorting based on visual characteristics such as color, size, and defects. This ensures that carrots are accurately categorized, leading to consistent product quality.

- Enhanced Product Quality: The machine effectively detects and removes defective or substandard carrots from the production line. This contributes to a higher overall product quality by ensuring that only visually appealing and healthy carrots reach consumers.

- Waste Reduction: By automatically identifying and removing defective or undesirable carrots, the optical sorter minimizes waste. This results in a more efficient use of resources and reduces the environmental impact of waste disposal.

- Improved Efficiency: Optical sorters operate at high speeds, facilitating rapid sorting of carrots. This increased efficiency is especially crucial in large-scale carrot processing operations, where high throughput is essential for meeting market demands.

- Color Sorting Capability: The machine excels at color sorting, allowing for the separation of carrots based on their color. This is important for meeting specific market preferences and ensuring uniformity in packaged products.

- Size Sorting for Uniformity: Optical sorters categorize carrots based on size, contributing to the creation of uniform batches for packaging. This is beneficial for meeting size specifications and providing consistency in the final product.

- Gentle Handling: Optical sorting machines are designed to handle carrots delicately, minimizing the risk of damage during the sorting process. This gentle handling helps preserve the integrity and appearance of the carrots.

- Customizable Settings: Operators can often customize sorting parameters to adapt the machine to different varieties of carrots and specific quality requirements. This flexibility allows for the accommodation of variations in carrot characteristics.

- Integration with Packaging Lines: Optical sorters are seamlessly integrated into larger carrot processing and packaging lines. This integration ensures a continuous and streamlined production process, from sorting to packaging.

- Reject System: The optical sorting machine incorporates a reject system to remove defective or off-spec carrots from the main product stream. This prevents inferior carrots from reaching the final packaged products.

- Data Collection and Reporting: Some optical sorting machines offer data collection and reporting features. This data can be valuable for quality control, traceability, and process optimization, allowing for continuous improvement in production practices.

The benefits of an optical sorting machine for carrots include improved accuracy, enhanced product quality, waste reduction, increased efficiency, and the ability to meet specific market requirements. These advantages contribute to the overall success and competitiveness of carrot processing operations.

Carrots are well-suited for packaging by an optical sorting machine due to several factors that align with the capabilities of this advanced technology:

- Diverse Color Varieties: Carrots come in various colors, including orange, purple, yellow, and white. Optical sorting machines are proficient in color recognition, allowing for accurate sorting based on different color criteria. This is valuable for creating visually appealing and market-compliant packaged products.

- Size Variability: Carrots exhibit size variations, and optical sorting machines can effectively sort them based on size. This ensures uniformity in packaged batches, meeting market standards and consumer expectations.

- Defect Detection: Optical sorters excel at detecting defects, such as blemishes, cracks, or misshapen parts. Carrots may have imperfections that impact their quality, and optical sorting machines contribute to the removal of defective items from the production line, enhancing overall product quality.

- Gentle Handling Requirements: Carrots are delicate vegetables prone to damage or bruising if handled roughly. Optical sorting machines are designed with gentle handling mechanisms to minimize the risk of physical harm during the sorting process, preserving the integrity of the carrots.

- High-Volume Processing: Carrots are commonly processed in large volumes due to their widespread consumption. Optical sorting machines operate at high speeds, making them suitable for handling the significant throughput required in large-scale carrot processing operations.

- Efficiency and Automation: Optical sorting machines bring efficiency and automation to the sorting process. They can rapidly and accurately analyze visual characteristics, contributing to streamlined operations and reducing the reliance on manual labor.

- Waste Reduction: By automatically identifying and removing defective or undesirable carrots, optical sorting machines contribute to waste reduction. This aligns with sustainability goals and ensures that only high-quality carrots reach the final packaged products.

- Market Requirements and Quality Standards: Carrots, like many other food products, are subject to market requirements and quality standards. Optical sorting machines help meet these standards by consistently sorting carrots based on predetermined criteria, ensuring that the packaged products meet regulatory and consumer expectations.

- Customizable Sorting Parameters: Optical sorting machines offer flexibility in adjusting sorting parameters to accommodate different carrot varieties and specific quality requirements. This adaptability is crucial for handling the inherent diversity in carrot characteristics.

- Integration into Production Lines: Optical sorting machines can be seamlessly integrated into larger carrot processing and packaging lines. This integration ensures a continuous and efficient flow from sorting to packaging, optimizing the overall production process.

The visual diversity, size variability, and sensitivity of carrots make them an ideal candidate for sorting by optical sorting machines. The capabilities of these machines align with the specific characteristics of carrots, resulting in enhanced efficiency, improved product quality, and waste reduction in the packaging process.