- Equipment

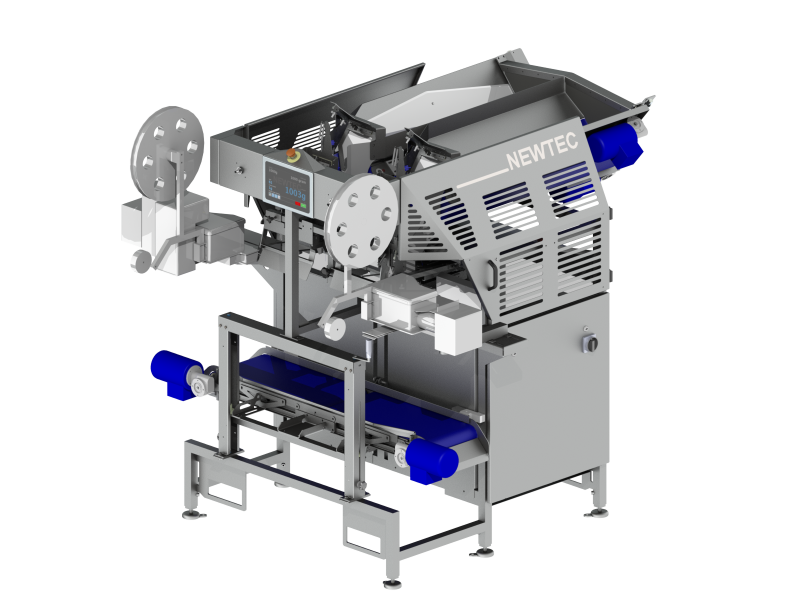

- NEWTEC PEB61

NEWTEC PEB61

NEWTEC PEB61

Details

Key Features and Benefits

- Full stainless-steel construction

- High capacity: Up to 50 bags per min. (2x25 bags)

- 2–20-pound bags works with poly, poly/mesh Combo, and full mesh wicketed bags

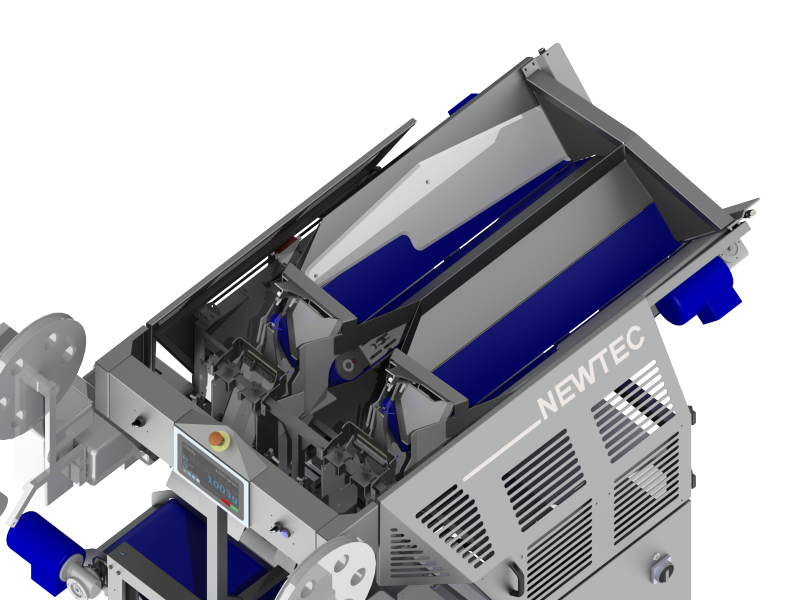

- Special infeed for large citrus

- Customised according to packaging type and product

- Reliable and easy to maintain

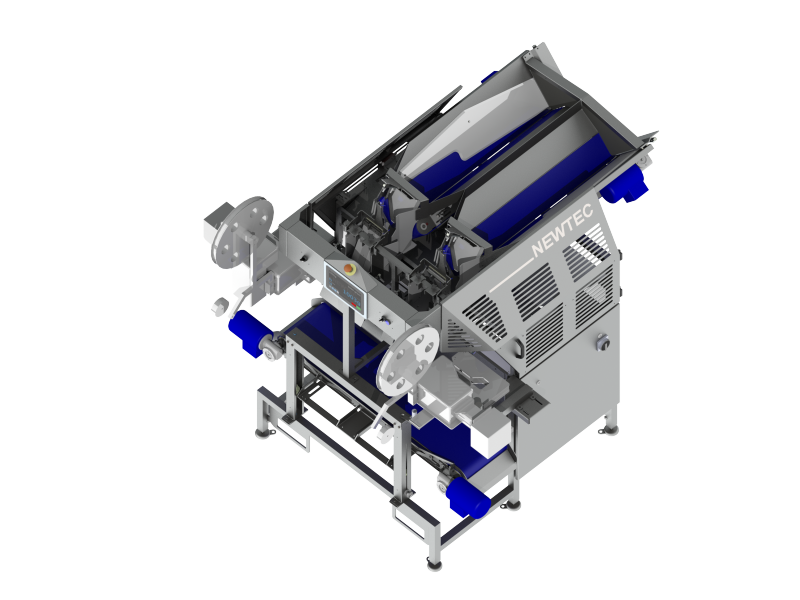

- Double wicketed bagger (2 bagging heads) for high-speed production

- Touch screen control panel with program storage

- Kwik-Loks mounted where they are accessible not under the conveyors where they get filled with debris

- Great machine for citrus, potatoes, bell peppers

- WebServices available for remote servicing and for capturing production data

- MachineLink enabled – from only one touchscreen, either on our weighing machine or our packing machine, model PEB61, recipe change and start/stop for both machines is possible

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions equipment for advanced automation in fresh produce packaging.

Works With

Details

Key Features and Benefits

- Full stainless-steel construction

- High capacity: Up to 50 bags per min. (2x25 bags)

- 2–20-pound bags works with poly, poly/mesh Combo, and full mesh wicketed bags

- Special infeed for large citrus

- Customised according to packaging type and product

- Reliable and easy to maintain

- Double wicketed bagger (2 bagging heads) for high-speed production

- Touch screen control panel with program storage

- Kwik-Loks mounted where they are accessible not under the conveyors where they get filled with debris

- Great machine for citrus, potatoes, bell peppers

- WebServices available for remote servicing and for capturing production data

- MachineLink enabled – from only one touchscreen, either on our weighing machine or our packing machine, model PEB61, recipe change and start/stop for both machines is possible

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions equipment for advanced automation in fresh produce packaging.

Downloads

Technical Specs

Speed

Up to 50 bags per min. (bag size or weight)

Capacity

Weight up to 10 kg

Material

According to the EU rules on food contact materials

Air Connection Requirement

3/8″

Air Minimum Pressure Requirement

6 bar (0.6 Mpa)

Air Consumption Requirement

260 NL/min.

Electrical requirement

3×230 VAC or 3×400 VAC (N) PE

50/60 Hz 2.5 kW

Environment

5ºC–40ºC

Weight

510 kg

About Company

Newtec is a leading manufacturer of weighing, packing and sorting machinery primarily for the fruit and vegetable industry. With more than 15,000 successful installations over the last 40 years, we have maintained our position as a reputable worldwide company. At Newtec, we pride ourselves on the ability to design solutions that meet your specific needs by combining our machines and the latest technology in new and innovative ways.

We have a reputation for developing, engineering and building high-quality, high-performance machines that our customers rely on.

We focus on building successful long-term relationships with our customers. Understanding your business and the potential challenges it faces is a critical step in order to deliver solutions that make an impactful difference.

FAQ

A dual bagger with a V belt refers to a packaging machine equipped with a V belt conveyor system that is designed to handle and fill two bags simultaneously. This type of bagging equipment is commonly used in industrial settings for efficiency in dual or parallel packaging operations. The “V belt” refers to the conveyor belt system that is shaped like the letter “V” and is a common design for conveying products in various industries.

Here are key features and components associated with a dual bagger with a V belt:

- Dual Bagger Configuration:

- The machine is configured to accommodate and simultaneously fill two bags during each packaging cycle. This dual configuration enhances productivity and throughput.

- V Belt Conveyor System:

- The V belt conveyor system is a type of conveyor belt arrangement that uses a V-shaped profile. This design allows for efficient and smooth transportation of products along the conveyor line.

- Product Feed System:

- The bagger is equipped with a product feed system that allows for the controlled and synchronized feeding of the product to the dual filling stations.

- Filling Stations:

- There are two filling stations, each corresponding to one of the bags being filled. These stations may include weighing mechanisms or volumetric fillers to ensure accurate and consistent product quantities in each bag.

- Sealing Mechanism:

- After filling, the bags move to a sealing mechanism that securely closes and seals each bag. This can include heat sealing, ultrasonic sealing, or other sealing methods depending on the bag and product specifications.

- Control System:

- The machine is equipped with a control system that manages the entire packaging process. Operators can set parameters, monitor the filling and sealing operations, and make adjustments as needed.

- Adjustable Settings:

- The dual bagger with a V belt typically has adjustable settings to accommodate different bag sizes, product types, and packaging requirements. This flexibility allows for customization based on specific production needs.

- Durability and Stability:

- These machines are designed for durability and stability to ensure consistent and reliable performance during extended periods of operation.

- Integration with Additional Equipment:

- Dual baggers with V belts can often be integrated into larger packaging lines, allowing for seamless coordination with other equipment such as weighing scales, labeling machines, and conveyors.

- Versatility:

- The versatility of the machine makes it suitable for various industries, including food processing, agriculture, chemicals, and more, where dual packaging is required for efficiency.

The dual bagger with a V belt is a solution tailored for high-volume packaging applications where the simultaneous filling of two bags optimizes the overall efficiency of the packaging process. It is commonly used in industries where speed, precision, and dual packaging capabilities are essential.

A dual bagger with a V belt offers several benefits, making it a valuable piece of packaging equipment for industries requiring efficient and simultaneous filling of two bags. Here are key advantages associated with a dual bagger with a V belt:

- Increased Efficiency:

- Simultaneous filling of two bags during each packaging cycle significantly increases operational efficiency. This dual-bag configuration reduces the time required to fill and seal each bag individually, contributing to higher throughput.

- Optimized Throughput:

- The dual bagger is designed to handle higher production volumes, making it suitable for industries with demanding throughput requirements. The synchronized filling of two bags ensures a more streamlined and productive packaging process.

- Cost Savings:

- By doubling the packaging capacity per cycle, the dual bagger with a V belt helps reduce labor costs and overall production time. This can lead to cost savings and improved profitability for manufacturers.

- Space Efficiency:

- Combining dual packaging capabilities with a V belt conveyor system helps optimize space utilization on the production floor. This is especially beneficial in facilities where floor space is a consideration.

- Versatility:

- The machine’s versatility allows for the packaging of a wide range of products and bag sizes. Adjustable settings and customization options accommodate diverse production requirements, providing flexibility for different applications.

- Reduced Downtime:

- With dual bagging capabilities, the machine can maintain consistent production even if one bagging station requires maintenance or experiences a brief stoppage. This contributes to reduced downtime and ensures continuous operation.

- Consistent Filling:

- The dual bagger is equipped with mechanisms to ensure consistent and accurate filling of both bags. This precision helps maintain product quality and packaging consistency, meeting stringent industry standards.

- Integration with Packaging Lines:

- The dual bagger with a V belt can be seamlessly integrated into larger packaging lines, allowing for synchronized operation with other equipment such as weighing scales, labeling machines, and conveyors. This integration enhances overall line efficiency.

- User-Friendly Controls:

- The machine typically features a user-friendly control system that allows operators to easily set parameters, monitor the packaging process, and make adjustments as needed. This simplicity contributes to efficient machine operation.

- Durability and Stability:

- These machines are designed for durability and stability, ensuring reliable performance over extended periods. Robust construction contributes to a longer lifespan and reduced maintenance requirements.

- Adaptability to Different Industries:

- Dual baggers with V belts are versatile and find applications across various industries, including food processing, agriculture, chemicals, and more. Their adaptability makes them suitable for different packaging needs.

A dual bagger with a V belt provides benefits such as increased efficiency, optimized throughput, cost savings, space efficiency, versatility, and reduced downtime. These advantages make it a valuable asset in industrial settings where simultaneous dual bagging is essential for meeting production demands.

A dual bagger with a V belt is a versatile packaging machine that can handle a variety of fruits and vegetables. The simultaneous filling of two bags during each packaging cycle makes it suitable for high-throughput operations. Here are examples of fruits and vegetables that can be effectively packaged with a dual bagger featuring a V belt:

- Berries:

- Strawberries

- Blueberries

- Raspberries

- Blackberries

- Grapes:

- Red grapes

- Green grapes

- Seedless varieties

- Cherries:

- Sweet cherries

- Sour cherries

- Stone Fruits:

- Peaches

- Nectarines

- Plums

- Citrus Fruits:

- Oranges

- Mandarins

- Lemons

- Limes

- Apples:

- Small-sized apple varieties

- Pears:

- Small-sized pear varieties

- Kiwi:

- Kiwifruit

- Melons:

- Cantaloupe

- Honeydew

- Pineapple:

- Pineapple chunks or slices

- Bananas:

- Small-sized or baby bananas

- Tomatoes:

- Cherry tomatoes

- Grape tomatoes

- Bell Peppers:

- Mini bell peppers

- Cucumbers:

- Baby cucumbers

- Carrots:

- Baby carrots

- Radishes:

- Mini radishes

- Zucchini:

- Baby zucchini

- Broccoli:

- Broccoli florets

- Cauliflower:

- Cauliflower florets

- Snap Peas:

- Baby snap peas

- Green Beans:

- Baby green beans

- Asparagus:

- Thin asparagus spears

- Brussels Sprouts:

- Baby Brussels sprouts

- Mushrooms:

- Small-sized mushrooms

- Leafy Greens:

- Baby spinach

- Baby kale

- Fresh Herbs:

- Cilantro

- Parsley

- Basil

- Avocado:

- Sliced or diced avocado

- Radishes:

- Baby radishes

- Microgreens:

- Various microgreen varieties

- Mixed Vegetable Packs:

- Assorted vegetable packs containing a combination of small-sized vegetables

These examples demonstrate the versatility of a dual bagger with a V belt in handling various fruits and vegetables. The machine’s ability to fill two bags simultaneously makes it well-suited for the efficient and high-throughput packaging of a wide range of produce in the food industry.