- Equipment

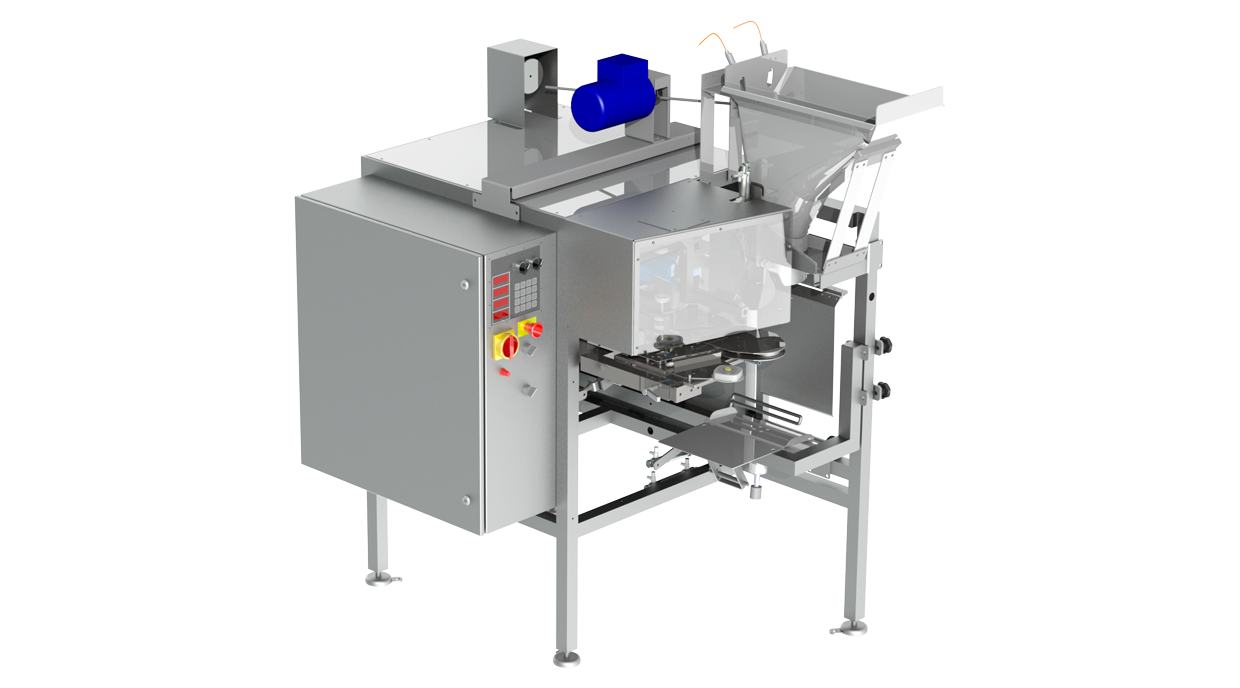

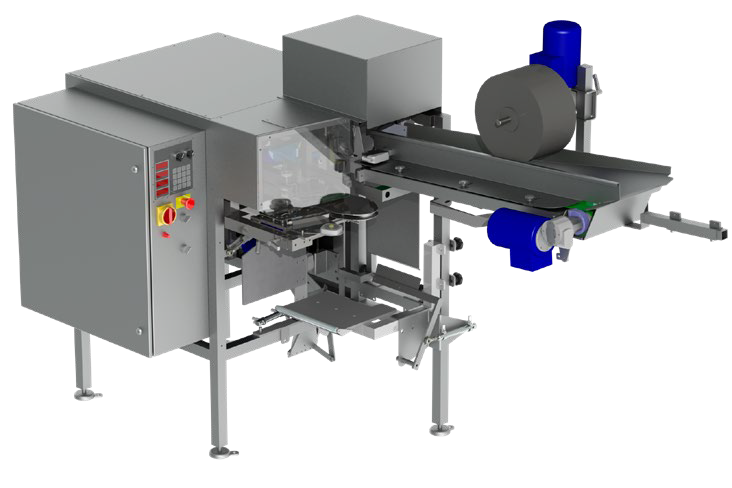

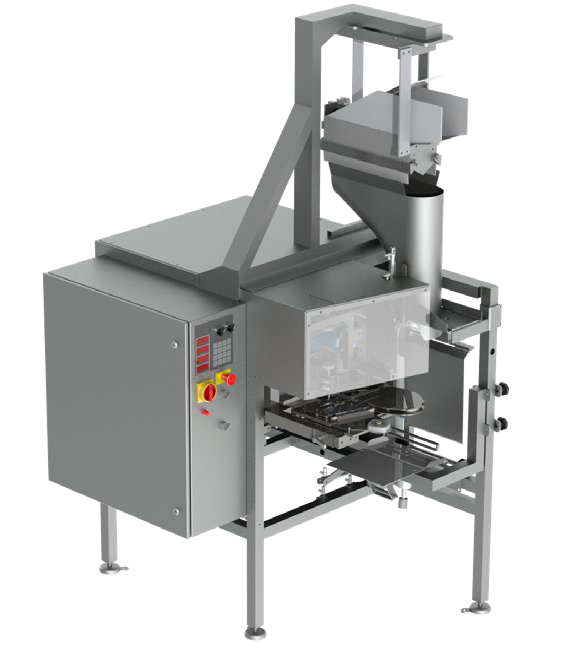

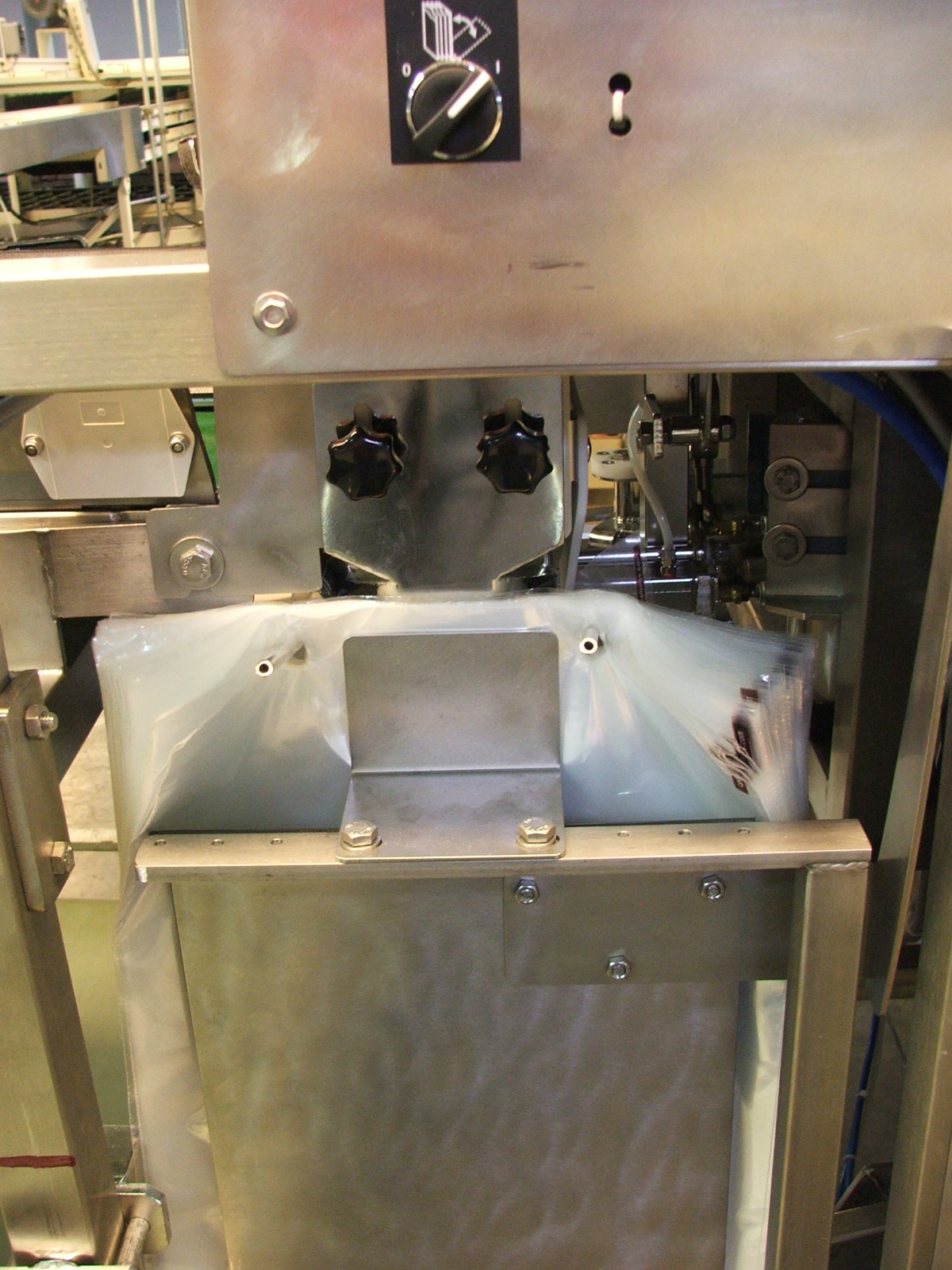

- NEWTEC PEB40AE

NEWTEC PEB40AE

NEWTEC PEB40AE

Details

Key Features and Benefits

- Full stainless steel construction

- Adjustable fill opening

- Variable speed bag feed belt

- Electric variable speed soft touch product lowering plate to gently fill bags

- Program storage

- Works with wicketed bags from 2-10 pounds

- Works with poly, poly/mesh Combo and full mesh wicketed bags

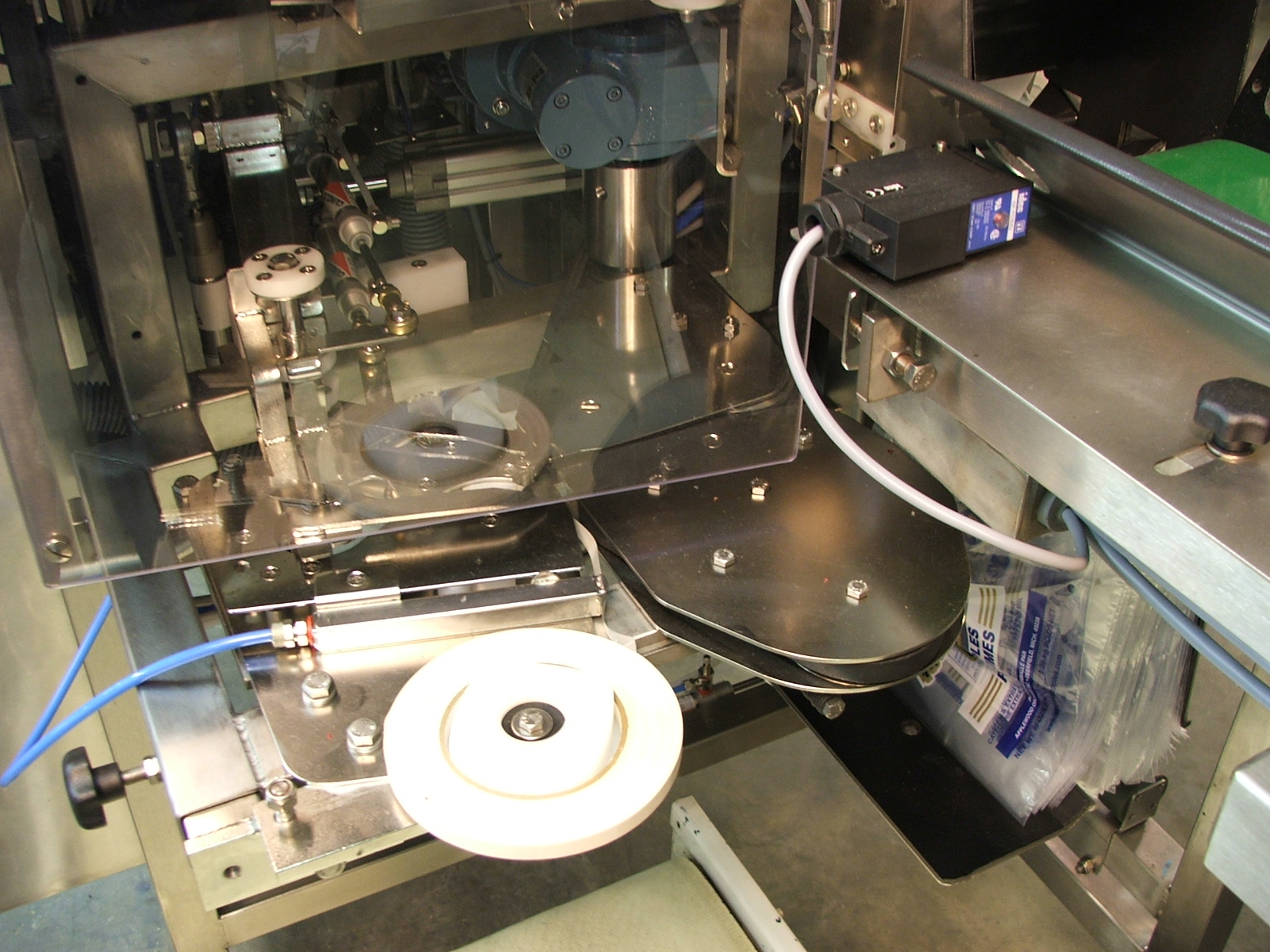

- Tape closure-less costly bag closure with tamper evidence

- Tape printer optional for bag coding

- Optional Kwik-Lok closure

- Ideal for apples, pears, kiwi, tomatoes, fragile sweet potatoes

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions equipment for advanced automation in fresh produce packaging.

Works With

Details

Key Features and Benefits

- Full stainless steel construction

- Adjustable fill opening

- Variable speed bag feed belt

- Electric variable speed soft touch product lowering plate to gently fill bags

- Program storage

- Works with wicketed bags from 2-10 pounds

- Works with poly, poly/mesh Combo and full mesh wicketed bags

- Tape closure-less costly bag closure with tamper evidence

- Tape printer optional for bag coding

- Optional Kwik-Lok closure

- Ideal for apples, pears, kiwi, tomatoes, fragile sweet potatoes

Visit Newtec at www.newtec.com for more information.

See all Fox Solutions equipment for advanced automation in fresh produce packaging.

Downloads

Technical Specs

Speed

Up to 25 bags per min.

Capacity

Weight up to 5 kg

Bag size

H=300mm-550mm

W=220mm-320mm

Material

According to the EU rules on

food contact materials

Air Connection Requirement

3/8”

Air Minimum Pressure Requirement

6 bar (0.6 Mpa)

Air Consumption Requirement

130 NL/min.

Electrical Requirement

3×230 VAC or 3×400 VAC (N)

PE 50/60 Hz 1 kW

Environment

5ºC–40ºC

Weight

320 kg

About Company

Newtec is a leading manufacturer of weighing, packing and sorting machinery primarily for the fruit and vegetable industry. With more than 15,000 successful installations over the last 40 years, we have maintained our position as a reputable worldwide company. At Newtec, we pride ourselves on the ability to design solutions that meet your specific needs by combining our machines and the latest technology in new and innovative ways.

We have a reputation for developing, engineering and building high-quality, high-performance machines that our customers rely on.

We focus on building successful long-term relationships with our customers. Understanding your business and the potential challenges it faces is a critical step in order to deliver solutions that make an impactful difference.

FAQ

A fully automatic wicketed bagger designed for gentle handling of soft fruit is a specialized packaging machine tailored for the delicate nature of soft fruits. This type of bagging equipment is engineered to handle fruits with care, minimizing bruising or damage during the packaging process. The term “wicketed” refers to the method of bag dispensing where bags are mounted on a wicket for easy loading onto the bagger. Here are key features and functions of such a machine:

- Gentle Product Feed:

- The bagger incorporates mechanisms that ensure the gentle and controlled feeding of soft fruits into the packaging area. This helps prevent squeezing or bruising of the fruits.

- Wicketed Bag Dispensing:

- Bags are mounted on a wicket for convenient and quick loading onto the bagger. This design ensures a smooth and continuous bagging process.

- Automatic Bag Opening:

- The machine is equipped with an automatic bag-opening mechanism to minimize manual handling and reduce the risk of fruit damage during the bagging process.

- Soft Handling Belts or Conveyors:

- The conveying system of the bagger is designed with soft, non-abrasive belts or conveyors to further protect the soft fruits as they move through the packaging stages.

- Customizable Parameters:

- Operators can typically adjust the machine’s parameters to accommodate different sizes, shapes, and varieties of soft fruits. This customization ensures adaptability to various fruit types.

- High-Speed Operation:

- Fully automatic wicketed baggers for soft fruit are designed for high-speed operation to meet the demands of large-scale fruit packaging operations.

- Integration with Weighing Systems:

- These baggers can be integrated with automatic weighing systems, such as multi-head weighers or other precision scales, to ensure accurate portioning of soft fruits into each bag.

- Sealing Mechanism:

- The bagger incorporates a sealing mechanism to securely close and seal each bag after it is filled with the desired quantity of soft fruit.

- User-Friendly Interface:

- The machine is equipped with a user-friendly interface that allows operators to set parameters, monitor the packaging process, and make adjustments as needed.

- Adaptable for Various Soft Fruits:

- The design of the bagger takes into account the diversity of soft fruits, including berries, grapes, cherries, and other delicate varieties. It is adaptable to handle different fruit sizes and shapes.

- Reduced Product Waste:

- The gentle handling and precise portioning capabilities contribute to reduced product waste, ensuring that a higher percentage of soft fruits make it to the final packaged products.

- Compliance with Quality Standards:

- Fully automatic wicketed baggers for soft fruit are designed to comply with industry quality standards, ensuring that the packaging process meets regulatory requirements and maintains the quality of the fruit.

- Hygienic Design:

- The machine is often designed with hygienic features to meet the cleanliness and food safety requirements of the food industry.

A fully automatic wicketed bagger designed for gentle handling of soft fruit is a specialized packaging solution that prioritizes the delicate nature of these fruits. The combination of features such as wicketed bag dispensing, automatic bag opening, customizable parameters, and gentle handling mechanisms makes it suitable for the efficient and careful packaging of soft fruits in large-scale production environments.

A fully automatic wicketed bagger designed for gentle handling of soft fruit offers several benefits, particularly tailored to the delicate nature of these fruits. Here are key advantages associated with such a specialized packaging machine:

- Minimized Fruit Damage:

- The primary benefit is the minimization of fruit damage during the packaging process. The gentle handling mechanisms and soft conveyors ensure that soft fruits, such as berries or grapes, are treated with care, reducing the risk of bruising or deformation.

- Preservation of Fruit Quality:

- By prioritizing gentle handling, the bagger helps preserve the quality of soft fruits. This is crucial for maintaining the appearance, flavor, and texture of the fruits, meeting consumer expectations for high-quality produce.

- Reduced Product Waste:

- The precise and gentle handling of soft fruits contributes to a reduction in product waste. Fewer damaged or bruised fruits mean a higher yield of usable product, minimizing losses and enhancing overall operational efficiency.

- High-Speed Operation:

- Fully automatic wicketed baggers are designed for high-speed operation, ensuring that the packaging process remains efficient and meets the demands of large-scale fruit packaging operations without compromising on gentle handling.

- Optimized for Various Soft Fruits:

- The adaptability of the machine for various soft fruits allows it to handle different sizes, shapes, and varieties. This versatility is essential for packaging operations dealing with a diverse range of soft fruits.

- Integration with Weighing Systems:

- The seamless integration with automatic weighing systems ensures accurate portioning of soft fruits into each bag. This precision contributes to consistent product weights and packaging quality.

- User-Friendly Interface:

- Equipped with a user-friendly interface, the machine allows operators to easily set parameters, monitor the packaging process, and make adjustments as needed. This ease of use enhances operational efficiency.

- Compliance with Quality Standards:

- Designed with industry quality standards in mind, the bagger ensures compliance with hygiene and food safety requirements. This is particularly important in the food industry where maintaining cleanliness and product integrity is essential.

- Hygienic Design:

- Many fully automatic wicketed baggers for soft fruit are designed with hygienic features, facilitating easy cleaning and ensuring that the packaging process adheres to strict hygiene standards.

- Improved Product Presentation:

- The gentle handling contributes to improved product presentation. Consumers receive fruits that are visually appealing and undamaged, enhancing the overall perception of the product.

- Adaptability to Different Packaging Needs:

- The machine’s customizable parameters allow for adjustments to accommodate various packaging needs, including different bag sizes, weights, and packaging formats.

- Cost-Efficient Packaging:

- By minimizing product waste, preserving fruit quality, and optimizing operational efficiency, the bagger contributes to cost-efficient packaging. This is beneficial for the economic viability of the packaging process.

A fully automatic wicketed bagger designed for gentle handling of soft fruit provides a range of benefits that collectively contribute to preserving fruit quality, reducing waste, and ensuring efficient and hygienic packaging operations in the production of soft fruits.

A fully automatic wicketed bagger designed for gentle handling of soft fruit is versatile and can efficiently package various types of delicate fruits. Here are examples of soft fruits that can be effectively handled and packaged using such a specialized bagging machine:

- Berries:

- Strawberries

- Blueberries

- Raspberries

- Blackberries

- Grapes:

- Red grapes

- Green grapes

- Seedless varieties

- Cherries:

- Sweet cherries

- Sour cherries

- Stone Fruits:

- Peaches

- Nectarines

- Plums

- Apricots:

- Fresh apricots

- Kiwi:

- Kiwifruit

- Fig:

- Fresh figs

- Pomegranate Seeds:

- Packaged pomegranate seeds

- Mango Chunks:

- Fresh or frozen mango chunks

- Pineapple Chunks:

- Fresh or frozen pineapple chunks

- Melons:

- Cantaloupe

- Honeydew

- Papaya:

- Fresh papaya

- Passion Fruit:

- Packaged passion fruit

- Cranberries:

- Fresh or dried cranberries

- Gooseberries:

- Fresh gooseberries

- Currants:

- Red or black currants

- Kumquats:

- Fresh kumquats

- Dragon Fruit (Pitaya):

- Packaged dragon fruit

- Tomatoes (Soft Varieties):

- Cherry tomatoes

- Grape tomatoes

- Sliced Peaches or Pears:

- Soft fruit slices for convenience

- Bilberries:

- Fresh or frozen bilberries

- Mulberries:

- Fresh mulberries

- Rambutan:

- Packaged rambutan

- Lychee:

- Fresh or peeled lychee

- Soft Fruit Medley:

- Mixed packages of assorted soft fruits

These examples represent a diverse range of soft fruits commonly found in the market. The fully automatic wicketed bagger is designed to handle these fruits with care, ensuring gentle processing and packaging. The versatility of the machine allows for efficient packaging of different soft fruit varieties, meeting the specific needs of the food industry.